Lunch & Learn session presenting a mobile solution for Jensen Precast.

Several individual stages can be identified In a typical manufacturing process. Not all production facilities have the same characteristics. Some require a more complex process that extends beyond the shop floor. One example is our customer, Jensen Precast. A company that manufactures concrete products for infrastructure in the US.

Novacura Lunch & Learn session hosted Josh Burns, Software Developer Manager, and Sophia Harrigan, programmer at Jensen Precast. During the session, the participants shared important information about the use of Novacura Flow in their operations. They reached a milestone by improving their processes.

Support manufacturing with digital POD

A common problem in manufacturing plants is not just about operations on the shop floor. Companies that offer non-standardized manufacturing processes must ensure that the production process can be secured from end-to-end. This approach includes a part of logistics that is closely related to the delivery process. One aspect that is required as part of delivery is POD (proof of delivery).

How does POD work in THE logistics environment?

Companies use fixed paper work to confirm deliveries. POD as a document must confirm the final delivery to the destination at the customer’s premises. The paper work is transferred to digital format as a scanned document, but its form is limited to a PDF sent only by e-mail. This approach is still very insufficient. There are several problems that can affect operations that use printed POD:

- Damage or loss of the document – the documentation must be constantly moved from hand to hand, which can cause easily damage or lose the document;

- Data discrepancies – the paper POD is handwritten with a pen, so the shipping details are often unreadable. Once the document is entered into the system, shipment details are incorrect;

- Incomplete data – data on the POD may be incomplete because some details were omitted when administrators manually filled out the document;

- Time-consuming process – making scanned copies of POD documents by overloaded transport administrators is time-consuming and very disturbing during a highly busy period;

- Confirmation of the document – the customer as a POD recipient cannot simply confirm the credibility of the document by taking the paper in hand from the driver. This operations must be always double checked with PC or through the phone in case of discrepancies etc.

POD problems can easily affect several different areas of the business with a direct link to the outcome in the manufacturing industry. A missing or incorrect document can cost an enormous amount of time.

Improvement solution

Even very qualified personnel has limited possibilities to create sufficient POD solution within short period of time. It’s not a just conclusion but reliable fact from the software developers. Difficulties with founding outside software solution and connect this directly to existing ERP systems is a common problem in every industry.

Jensen Precast decided to streamline its operations with a digital POD system. Creating a working solution in a short period was a major challenge. They reached out to outside experts in manufacturing and transportation. It turned out that a simple way to create a sufficient path for a digital POD was the approach proposed by Novacura software developers. Novacura consultants working with their own product, Novacura Flow Studio, were able to create a proof of concept for a POD in less than an hour.

Novacura folks came out and build up basically an identical proof of concept in about 45 min.

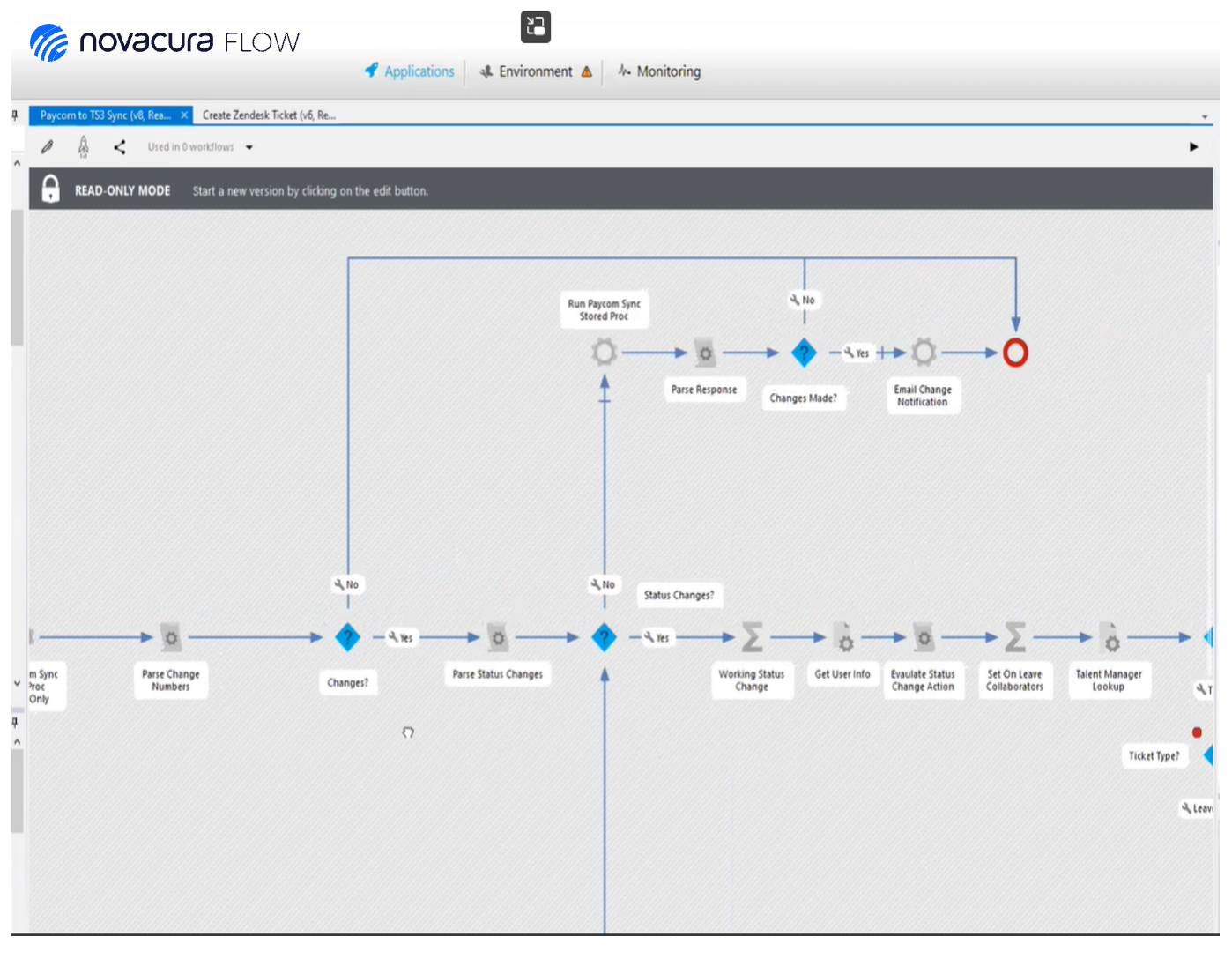

Using Novacura Flow Studio, Jensen Precast was able to create a comprehensive application linked to their existing ERP IFS. Integration with the ERP system allows for smooth data exchange between Novacura applications.

Novacura Flow Studio allows users to develop applications using a simple interface (snapshot above: Novacura Flow Studio interface). Users can create their own process in pipeline overviews and combine several options in a user-friendly environment without requiring high programming skills.

Efficient and secure delivery FROM manufacturing

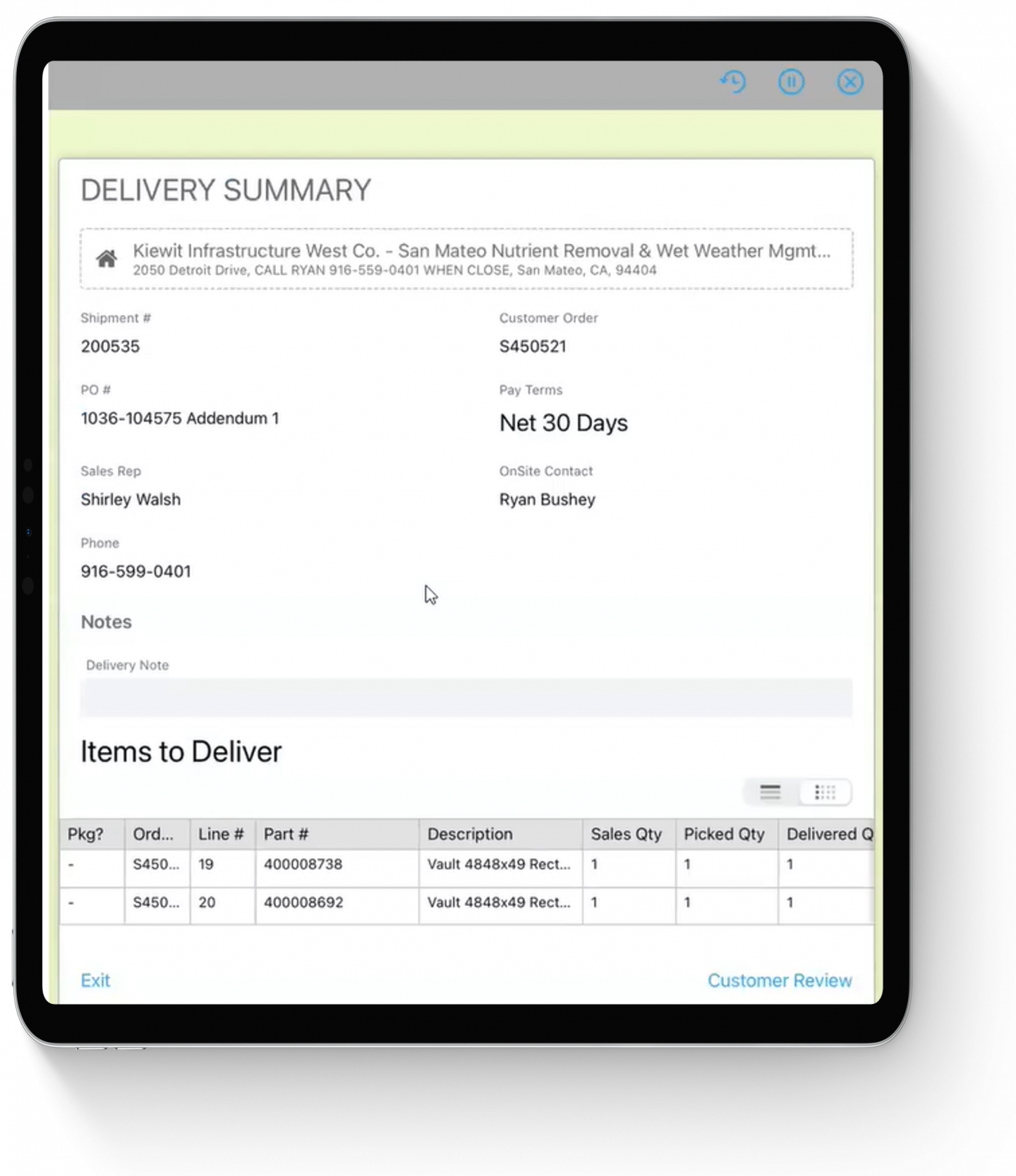

Using Novacura Flow Studio, the Jensen Precast team created an application that was able to track a range of transportation activities from production to the end customer. The application created by Jensen Precast developers has the following features:

- Define app user – person using application can use own login credentials that allow to track all performed operations;

- All-over recognition – application functions recognize location of the truck and allow to review shipments at the same time;

- Get active Shipment on Truck – driver can choose shipment and truck for delivery;

- Updates – application user is able upload to the system photos directly with his mobile device. Connected application with ERP system;

- Get Approver Info – once shipment is delivered system can confirm delivery;

- Get Shipment Comparison Info – system exchange all the data in the system and confirm it with existing details in ERP system (data exchange in ERP system);

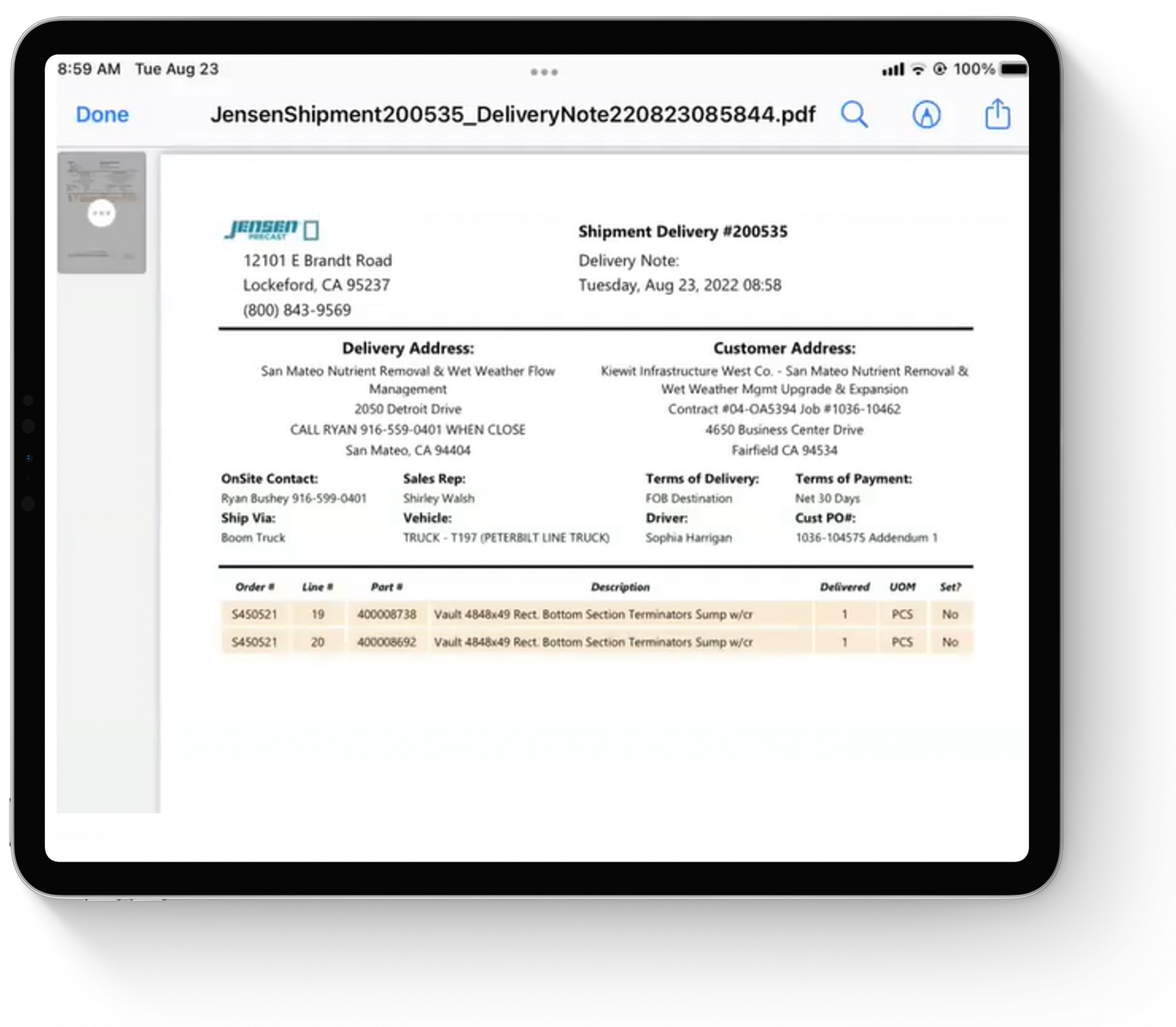

- Creating digital POD – digital POD is converted into PDF format for final review with an option to implement any changes (if needed);

- POD communication – digital POD in PDF is distributed via email throughout the network, including end customers, Jensen Precast and all required recipients;

All functions built into the application have been developed for Jensen Precast’s internal needs.

There is something that they use every day. Primarily used by truck drivers. That can use tablet for doing their day-to-day tasks.

Here are highlights from the app features used on tablet:

Once the consignment is delivered, the user can review all details related to the shipment. Anything incorrect will be automatically highlighted and can be adjusted (snapshot above).

Application used by Jensen Precast have several options, that allow to truck their drivers and deliveries with GPS function (snapshot above).

The final POD is generated after the delivery is received. The document is distributed throughout the network via email to customers and all required receipts (snapshot above).

Lunch & Learn session with Jensen Precast

Josh Burns, Software Developer Manager at Jensen Precast, explains during an online session how much support his company receives from software provided by Novacura.

Values and Benefits

Novacura Flow software offers several features. One of those is access to Novacura Flow Studio. Applications created in Novacura Flow Studio bring to business several important benefits.

- No more delays – documents are always in place thanks to the digital connection.

- Lack of documentation errors – no more handmade errors on paperwork. Visible notification in the app about possible errors.

- The system is always up-to-date – real-time updates in the ERP system integrated with the app (including the ability to upload photos).

- No overloading of employees – no additional time-consuming administrative tasks related to making scanned copies and sharing information.

- A single solution – 1 application with the ability to perform several different operational tasks in a user-friendly environment.

Summary

POD has become a challenge in the area of delivery process optimization. Therefore all should be supervised from the very beginning to avoid problems that can impact several entire processes.

Jensen Precast using Novacrua Flow Studio has developed several different solutions for their internal operational needs. Our solution helps them a lot with mobile development against IFS, desktop applications and headless back with flows for migration and synchronization of data.

Novacura offers its solutions to several different industries. Applications can be developed to meet a variety of operational needs. If your organization needs a flexible solution to extend the capabilities of your ERP system, our Novacura Flow software product can provide a wide range of ready-to-use applications. Our consultants have extensive experience in many areas of system integration and implementation. We’re experts in ERP system solutions.

Contact us today and see how we can extend the capabilities of your ERP system.