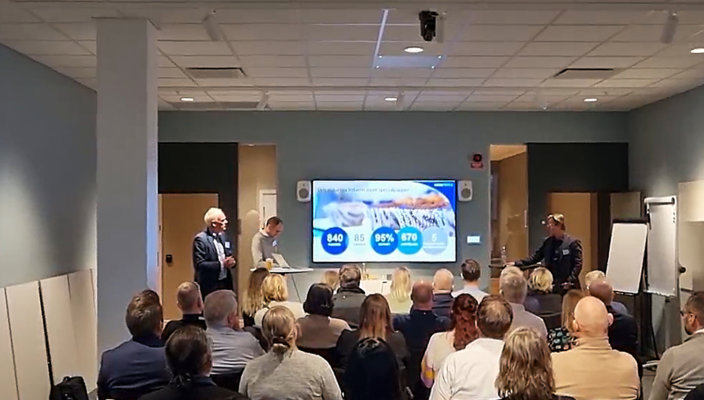

Specma Hydraulic is the market-leading supplier in Scandinavia of application-based hydraulic systems, and offers a wide range of hydraulic and pneumatic components as well as fluid conveyance systems.

Results of continuous search for improvement in Specma let to discover that warehouse process could contribute to increased productivity in the warehouse and higher service level compliance for clients.

Solution chosen by Specma was to install Novacura Flow barcode system with a barcode scanner. As a results, the quality of input data is very high, and the work process is significantly faster.

The main result is a well-organized and high-quality warehouse process as all data is registered just once. The system takes care of lots of tasks which were previously done by hand. Commissioning was quickly and problem-free and the project stayed within the time frame- It´s simple economics – the earlier in Specma implement a more efficient process, the more financial assets could company protect.

Thanks to this solution, warehouse workers have increased their efficiency by about 30 percent, and the error rate has dropped radically.

Novacura has developed a barcode system for Specma warehouse. Company inventory included different articles, and many of these look very similar. With barcode scanning system employers can be sure that the item number corresponds to the actual item. The system will let know if personnel making a mistake.

Thanks to this solution, warehouse workers in Specma have increased their efficiency by about 30 percent, and the error rate has dropped radically. The barcode system reports directly to the business system. Integration allow do an inventory any time without having to call in staff over the weekend.

Most players in the different markets have processes and workflows that are unique to each client. Instead of buying a standard system without adjusting it to your own operations, there is a lot to gain from adapting the system to your own operations, which is what Novacura has done for us.