Novacura Partners with 8to7 Solutions in the UK & Ireland

We are proud to announce our new partnership with 8to7 Solutions, an ambitious technology consultancy based in the United Kingdom. With a sharp focus on ERP, digital transformation and business process innovation, 8to7 Solutions joins Novacura as our exclusive official partner in the UK and Ireland. This collaboration combines Novacura’s low-code platform with 8to7 Solutions’ deep ERP expertise, ensuring that businesses across industries can operate faster, smarter and with greater confidence. About 8to7 Solutions 8to7 Solutions specialises in enterprise resource planning (ERP) consultancy, implementation, upgrades and support, helping organisations design, implement and optimise secure and future-proof business systems. Their team of ERP specialists, solution architects and developers operate at the intersection of business and technology, blending deep process knowledge with technical expertise. Their approach is built around speed, security and adaptability: projects are delivered quickly and efficiently, without compromising compliance or quality. With expertise spanning IFS, SAP, Infor M3, Prophet and Microsoft Dynamics, the company helps customers accelerate operations through ERP integration, automation, low-code solutions, mobile applications, and advanced analytics. Industries served 8to7 Solutions brings experience across a wide range of sectors, including: Manufacturing & Production – shop-floor visibility, planning and quality control Automotive, Aerospace & Defence – compliance-driven ERP and secure supply chain management Food & Beverage, Pharmaceuticals & Life Sciences – traceability, compliance and R&D support Energy & Utilities, Engineering & Construction – scalable asset management and field solutions Field Services & Professional Services – mobile, offline-first tools for scheduling and workforce optimisation Public Sector, Healthcare, Finance and Education – secure, transparent and cloud-ready operations Logistics & Supply Chain – end-to-end visibility, resilient networks and warehouse automation Unique Competencies Beyond ERP delivery, 8to7 Solutions integrates emerging technologies that give businesses a competitive edge, such as: Artificial Intelligence (AI) & Machine Learning – predictive analytics and intelligent automation Internet of Things (IoT) – connecting ERP with devices for real-time visibility Data Mining & Advanced Analytics – extracting actionable insights from large data sets Optical Character Recognition (OCR) – digitising and automating workflows Low-Code Development – extending ERP without disrupting the core Cloud-native & Mobile Solutions – enabling modern, scalable digital ecosystems Why This Partnership Matters “We are truly excited to partner with Novacura as their exclusive official partner in the UK and Ireland. This collaboration brings together 8to7 Solutions’ deep expertise in digital transformation, change management, business process optimisation and ERP implementations with Novacura’s low-code platform, an innovative and truly one-of-a-kind solution with no comparables in the market.”— Sangeetha Seneviratne Agalakotuwa, Founder, 8to7 Solutions With Novacura Flow, 8to7 Solutions will be able to deliver timely, tailored and scalable solutions across any ERP platform. By extending ERP systems with modern mobile user experiences, supporting ERP-standard APIs, and ensuring minimal maintenance effort, this partnership ensures businesses can: Accelerate digital transformation while reducing costs Unlock new life in legacy ERP systems Streamline upgrades and maintenance Achieve measurable efficiency and resilience Shared Mission At the heart of this partnership is a shared vision. 8to7 Solutions’ mission is to empower organisations with secure, scalable and intelligent ERP solutions […]

learn more

7 Key Advantages of Implementing ERP in the Mining Industry

Mining demands huge upfront investment. Running a mine means managing expensive machinery, juggling complicated supply networks, meeting tough safety and environmental rules, and dealing with unpredictable market prices. A lot of mines don’t hit their targets — not because the rock is bad, but because their systems don’t talk to each other and decisions get made in silos. This is where IFS ERP for the mining industry makes a difference. Purpose-built for asset-heavy operations, IFS ERP provides an integrated platform that connects people, equipment, and processes — from the pit to the boardroom. Together with low-code extensions through Novacura Flow, mining companies gain the agility to boost efficiency today while preparing for the future. Here are seven key advantages of implementing IFS ERP in mining operations: 1. Real-Time Visibility Across Operations IFS delivers real-time dashboards unifying information from drill rigs, trucks, processing plants, and finance departments. This mining software eliminates silos, so managers no longer waste hours chasing spreadsheets or making phone calls. Instead, they get instant insight into production rates, equipment health, and fuel usage. Such visibility helps spot trends before they become costly — like declining ore grades or rising fleet consumption. With IFS, mines can resolve production bottlenecks faster while reducing downtime that directly affects profitability. 2. Optimized Equipment Maintenance Mining assets like crushers and ultra-class haul trucks cost millions. Unplanned breakdowns are profit killers. IFS ERP software for mining production includes advanced Enterprise Asset Management (EAM) that uses predictive analytics, automated scheduling, and complete maintenance histories. The result: fewer emergency repairs, longer component life, and annual savings reaching millions for mid-sized operations. Facilities can schedule interventions during planned windows, ensuring availability remains high. 3. Stronger Supply Chain and Logistics Control Mining supply chains span the globe — from explosives and tires to shipping concentrate overseas. An ERP like IFS shows a live, end-to-end view of orders, shipments, and stock. It also predicts what you’ll need from production and maintenance plans, helping you avoid stockouts. For outbound moves, it plans truck routes, rail slots, and port bookings to cut costs and keep output on schedule. 4. Integrated Financial and Project Management Finance in this sector is complex: royalties, multi-currency transactions, hedge accounting, and strict reporting requirements. Implementing IFS consolidates all information into a single financial truth. Automated royalty calculations, real-time cost per ton tracking, and project profitability analysis become standard. Activity-based costing even allows managers to compare expenses down to individual pits or blast patterns — supporting smarter, data-driven investment decisions. 5. Compliance, Safety, and ESG Management From regulations to environmental permits, compliance failures can stop production instantly. IFS automates these workflows with certification tracking, incident reporting, inspection scheduling, and full audit trails. The system also supports ESG reporting by monitoring emissions, waste management, and water quality. Mining industry software solutions like IFS ensure operations remain compliant, safe, and aligned with stakeholder expectations around sustainability. Why ERP implementations fail? Set the ERP implementation team Create an effective change management plan Communicate with diverse groups Download 6. Data-Driven Decision-Making and Predictive Analytics Facilities […]

learn more

AI in ERP Systems: Benefits of Using Artificial Intelligence

The integration of artificial intelligence in ERP systems represents one of the most significant technological shifts in business software today.

learn more

Novacura at IFS Connect Nordics (Sweden)

Novacura kicked off the month of May with an exciting presence at IFS Connect Nordics 2025, held on May 5–6 in Solna, Stockholm. The event gathered enterprise leaders, technology experts, and IFS users from across the Nordic region to share insights on how to drive innovation, improve resilience, and create long-term business value with IFS Cloud. As one of four conferences on our May calendar, IFS Connect Nordics provided the perfect platform for our team to engage with customers, discuss digital transformation strategies, and demonstrate how Novacura Flow helps extend and enhance the IFS ecosystem. Event Highlights: Cloud Strategy, AI, and Industry Insights This year’s agenda focused on the most pressing themes for IFS customers, offering both strategic overviews and in-depth customer stories. Key highlights included: The Next Chapter of IFS CloudA look into the latest developments and future roadmap for IFS Cloud, including AI integration and continued platform flexibility to support evolving enterprise needs. Manufacturing for a Digital WorldThis session explored how manufacturers are adapting operations through smart factory initiatives, cloud-enabled automation, and data-driven decision-making. AI in Training & OperationsSeveral talks emphasized how AI is reshaping not just software but also how employees are trained, empowered, and supported in their day-to-day workflows. Sustainability as StrategyReal-world examples showcased how IFS users are embedding sustainability into core business processes — not just as compliance, but as a competitive advantage. Throughout the event, the focus remained on how organizations can navigate rapid change, improve operational resilience, and harness the power of technology — especially AI and cloud — to remain agile in complex markets. At Booth No. 3, visitors had the opportunity to meet the Novacura team — Calle Göras, Fredrik Rosendahl, Östen Westman, and Ricard Lindgren — to learn how our low-code platform, Novacura Flow, empowers IFS customers to build tailored applications that bridge process gaps, reduce manual work, and improve user experience across departments. Whether the interest was in shop floor control system apps, workflow automation, or integration capabilities, we were thrilled to discuss how Novacura Flow can complement IFS Cloud and deliver fast, flexible business solutions. SUMMARY IFS Connect Nordics once again proved to be a valuable gathering of minds and a great showcase of the direction enterprise software is headed in the Nordic region. We’re proud to have been part of it, contributing to conversations around smart digital solutions for manufacturing and helping IFS customers get even more out of their systems. Thank you to everyone who stopped by our booth and shared ideas. We’re looking forward to continuing the dialogue at upcoming events throughout May — and beyond.

learn more

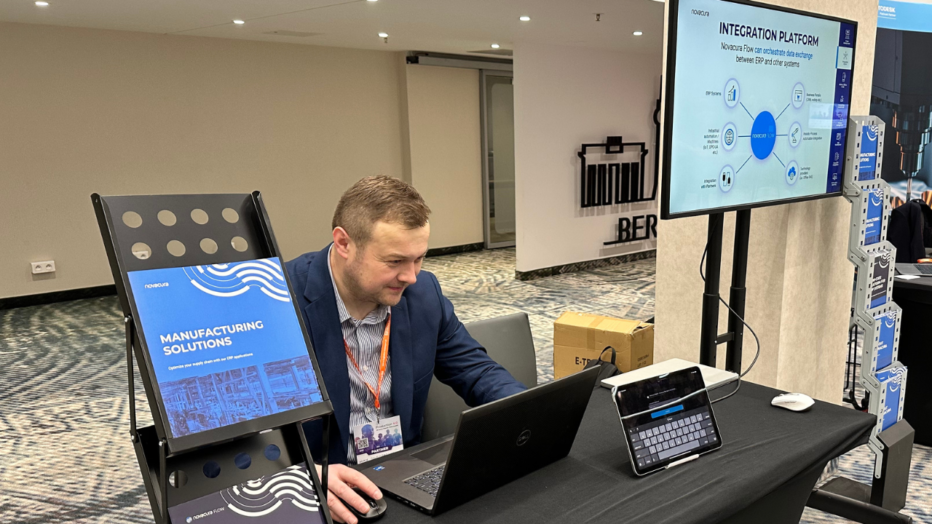

Novacura at M3UA UK Conference 2025: Showcasing Real-World Warehouse Optimization

As part of our ongoing event tour across the UK, Novacura was proud to participate in the M3UA UK Conference 2025, held on April 29 at the Leonardo Hotel Hinckley Island. This annual event brought together Infor M3 customers, experts, and partners to share insights and explore how to get more value out of their ERP environments. We were excited to return to this high-impact gathering — not only to connect with M3 users at our booth, but also to take the stage and present a powerful case study on warehouse operations optimization using Novacura Flow. Enhancing Full Pallet Picking with Novacura Flow At 16:30, Novacura’s Director of Sales, Aksel Jarlbäck, presented a customer case titled:“Enhancing Full Pallet Picking Efficiency with Novacura Flow.” The session addressed common challenges in traditional full pallet picking processes — such as manual scanning steps, repeated API calls, and process inefficiencies — which often result in delays, errors, and wasted time. Aksel walked the audience through a real-life implementation at a food and beverage company, showing how Novacura Flow was used to build a customized pallet picking application tailored to the customer’s needs. Key takeaways from the session included: How continuous scanning was implemented to streamline workflows How the app reduced manual input and operational time The measurable impact on accuracy and efficiency in the warehouse This case study provided a concrete example of how low-code automation can modernize M3 processes, especially in logistics-intensive environments. The audience had a chance to see how flexible application design — powered by Novacura Flow — can bridge ERP functionality gaps without requiring complex development or changes to the core system. SUMMARY Throughout the day, attendees also had the opportunity to stop by Novacura’s blue booth (#4) to meet Aksel Jarlbäck and Robin Huizer, discuss their own M3 challenges, and explore how low-code can be applied across operations — from warehousing to production and beyond. We were glad to engage with so many M3 professionals and share ideas on making ERP systems more user-friendly, efficient, and adaptable. Thanks to everyone who attended the session, visited our booth, and contributed to meaningful conversations. We look forward to returning next year and continuing the journey of ERP innovation — together.

learn more

Novacura Achieves ISO/IEC 27001:2022 Certification for Information Security

We’re proud to share that Novacura has officially achieved ISO/IEC 27001:2022 certification—a globally recognized standard for Information Security Management Systems (ISMS). This certification reaffirms our ongoing commitment to protecting data, ensuring security, and delivering trusted low-code digital transformation solutions to our clients. What This Means for Our Customers The ISO/IEC 27001:2022 certification, issued by Prescient Security LLC, confirms that Novacura operates an Information Security Management System that meets the strict requirements of the updated 2022 standard. It applies to our core services, including: Advisory and ERP consulting Implementation services for enterprise application integration Business process optimization Workflow automation This also covers consulting on the design, configuration, and deployment of digital transformation solutions—a crucial part of how we help businesses improve operational efficiency. Scope of Certification The certification specifically covers our use of the Azure cloud platform and includes several key departments: Corporate Management IT HR Finance Marketing We follow the practices laid out in the Statement of Applicability Version 4.0 (dated March 4, 2025), ensuring that our internal processes align with best-in-class security standards. Download the Certificate Here Why It Matters Data security and privacy are top priorities in today’s business environment. This certification validates that we take proactive, structured, and independently verified steps to protect our systems and the sensitive information our clients trust us with. A Team Effort Worth Celebrating We are incredibly proud of the entire Novacura team for the hard work and dedication that went into achieving this certification. From corporate management to IT and marketing, this was a cross-departmental effort that reflects our culture of excellence and accountability. We look forward to continuing to provide secure, reliable, and innovative solutions to our customers—now backed by an internationally recognized security standard.

learn more

May 17, 2023

May 17, 2023  5 min to read

5 min to read