Successful IFS Implementation in a Polish Subsidiary of a Swedish Company Nolato

In a dynamic business environment, the Polish branch of a Swedish company Nolato (a developer and manufacturer of products in polymer materials) faced operational inefficiencies due to outdated systems and manual processes. With the decision to implement IFS as their ERP system, the team aimed to enhance efficiency and streamline operations. This case study illustrates the challenges encountered, the solutions devised, and the overall impact of the ERP implementation, drawing insights from Novacura’s team members Andrzej Sałęga-Starzecki, Adam Szlembarski, Dorota Kopacka, and Patrycja Kowalska, who were responsible for the implementation. Additionally, notes from the customer side are included to provide deeper context and for the presented material. BACKGROUND: THE COMPANY AND ITS CHALLENGES The Polish branch of Nolato was facing challenges due to reliance on outdated methodologies, primarily using local legacy systems, Excel sheets, and manual processes. Recognizing the pressing need for modernization, they decided in 2022 to move forward with an IFS ERP implementation. Due to corporate requirements, the group implemented version 9 of the IFS system, with plans to upgrade to IFS Cloud in the future. The execution of this ERP system modernization was complex, requiring strategic planning and specialized expertise. Initial attempts to implement IFS in 2022 were unsuccessful, leading Nolato to engage Novacura as their IFS implementation partner. Key challenges included: Assembling a capable team familiar with IFS 9, suited to the specific needs of the Polish division. Configuring essential features like tax compliance and local reporting standards, requiring support from experienced consultants. Addressing compatibility issues between IFS 9 and the company’s manual processes, which relied heavily on physical records. With guidance from Novacura’s team in Stargard, Nolato successfully completed the project, setting the stage for future IFS upgrades and migrations. PROBLEM ANALYSIS AND PROPOSED SOLUTIONS The project kicked off in the second half of 2023, with the goal of completing it by year-end (the go-live phase occurred in June 2024). At the beginning, the project encountered a few problems, such as accessing an IFS support team proficient in IFS9, which was no longer supported by IFS, and correcting the previous Polish extension to IFS. Nolato had already tried to implement IFS in 2022 without major success. A significant challenge during the implementation process was also a data migration from an outdated, local database developed by a Szczecin-based company. The opening balance and initial data import were not problematic; however, preparing the data for migration proved to be more complex. The previous database used different terminologies, which required extensive training and clarification for the clients to understand the new IFS system’s requirements. Our consultancy team worked with Nolato, guiding them through the necessary adjustments. Adam Szlembarski Lead Business Systems Consultant at Novacura This hands-on approach ensured that the client’s team was well-equipped to handle the transition, which was also confirmed by the positive feedback from the Nolato side: The implementation process took place in a very friendly atmosphere. The consultants were always well-prepared and supportive. We tackled the assigned tasks gradually, which often required a great deal of flexibility on Novacura’s part. […]

learn more

Mobile approach to warehouse operations in Teknos

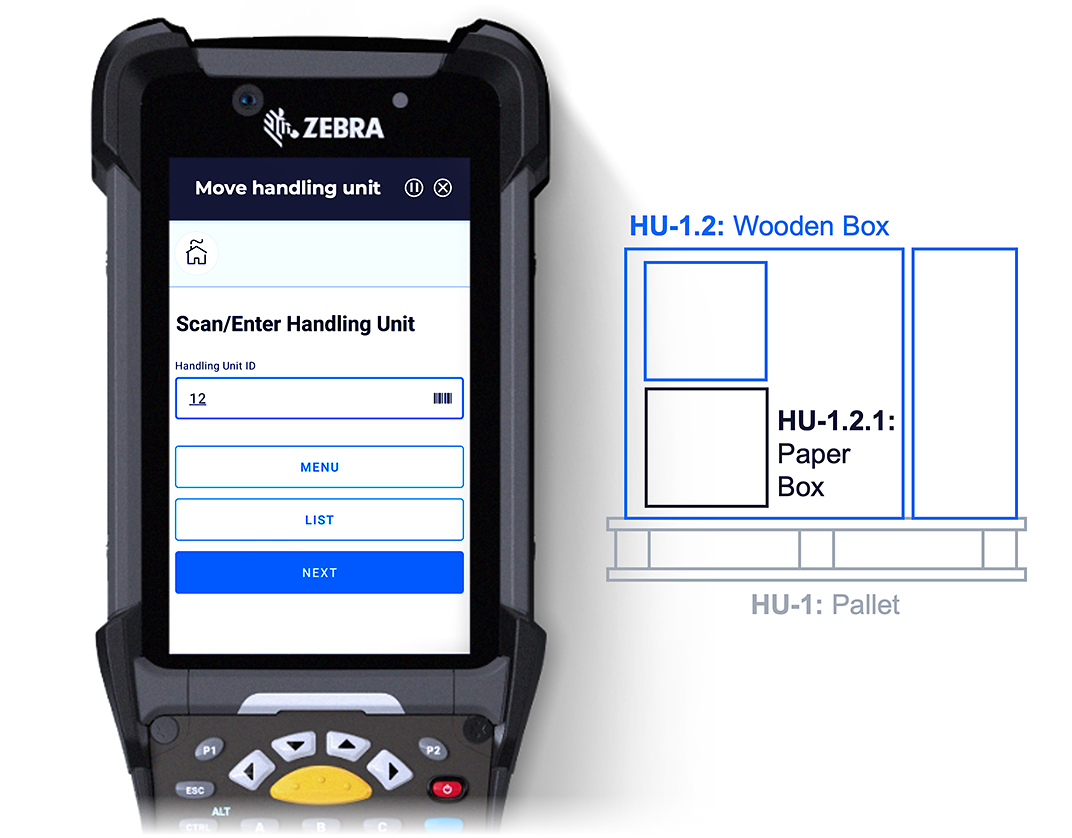

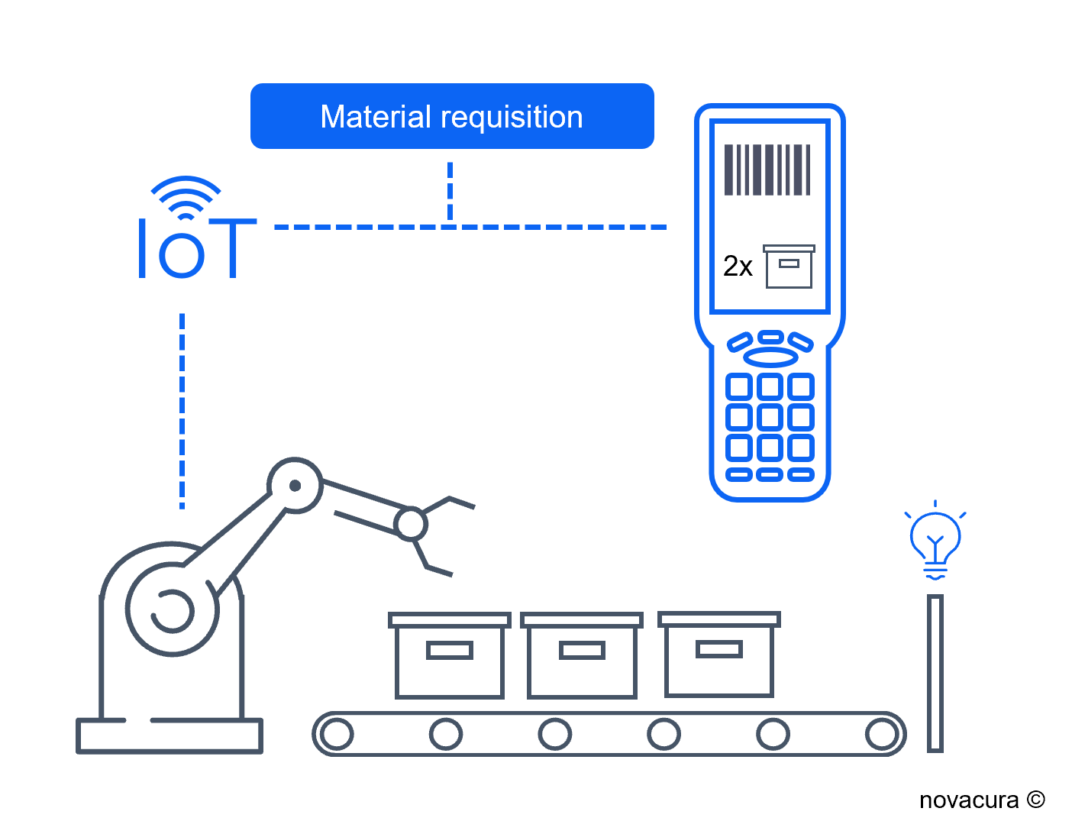

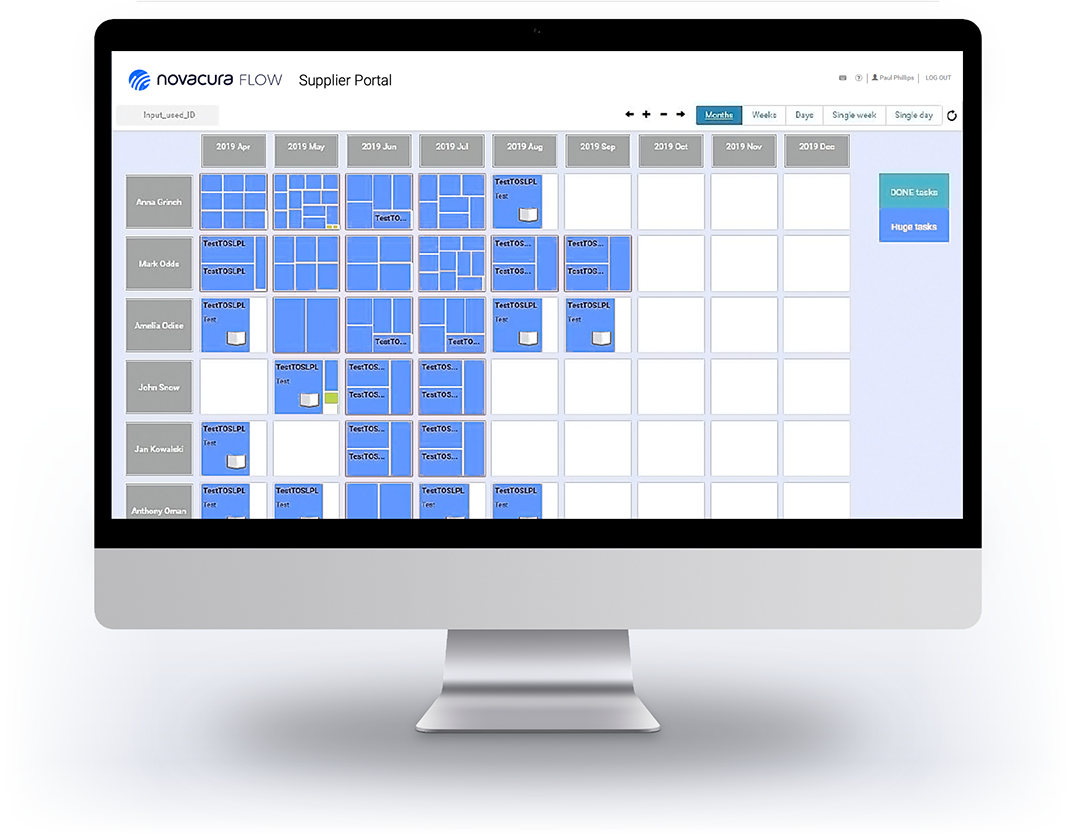

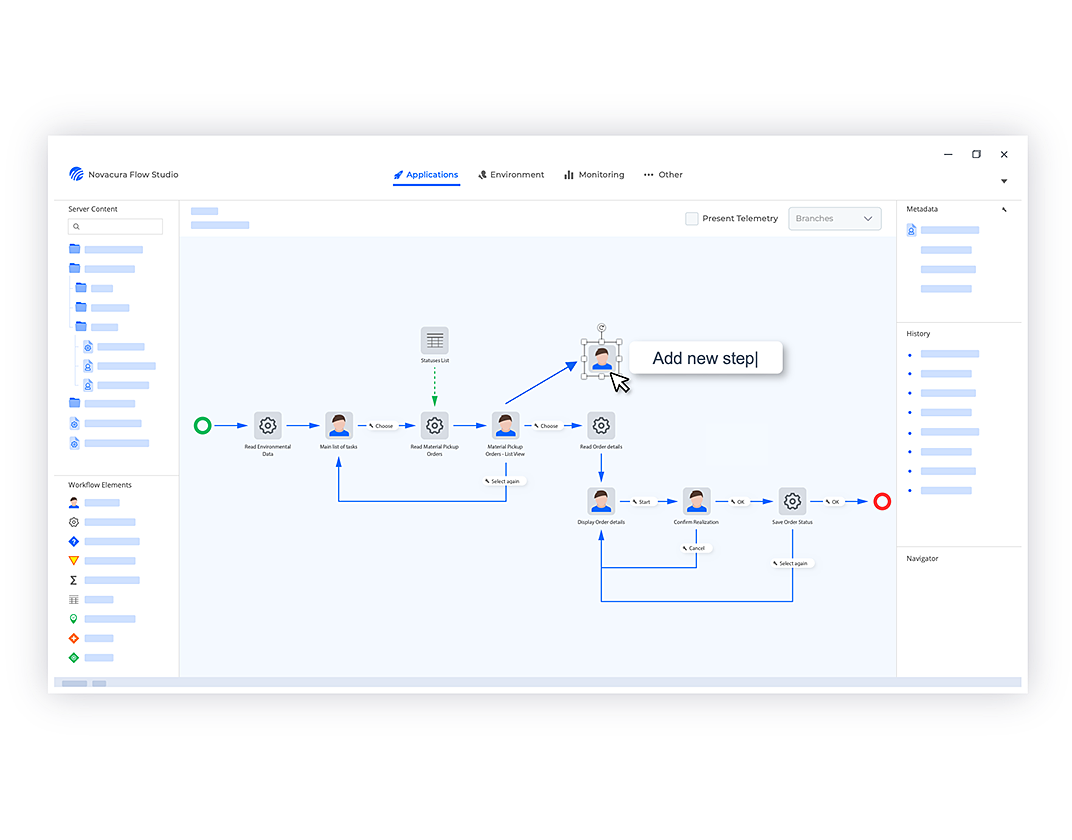

Manufacturing and logistics are closely interrelated on many levels. In a modern enterprise, attention is always on productivity and efficiency. Manufacturers have become very cognizant of the importance of measurement and obtaining data from different processes to create a holistic view of the entire business’s effectiveness. Improvements on the shop floor are the essential, but optimizations on the logistics and distribution side are required to accelerate maximum production cycle results. Smart internal logistics and inventory management are deeply integrated into production processes and are essential for efficient total process management (TPM). Focus on business improvement Most manufacturing companies these days are facing some serious problems that are crossing production and inventory management operations. It is crucial for these companies to correctly understand the root causes of the existing issues to clarify the requirements for improvement. Warehouse operations – inefficiencies in connecting the complexity of warehouse operations (order picking, inbound and outbound, inventory management) with the production floor can result in significant financial losses due to faulty packaging management, lack of good coordination of raw materials, utilization of scrap or damage detection. Modification problems – difficulties with modifications that are required to meet new business needs. The old software systems installed on the shop floor need to be more flexible to extend the business capabilities that are needed to manage day-to-day operations. Business solutions from Novacura Problems in operations with manufacturing and warehouse management can be solved with software solutions that can extend the capabilities of ERP systems with mobile and desktop applications. The most appropriate approach is using a solution that will not make changes to the structure of the ERP system itself but will connect independently on top of it and provide the user with the ability to implement continuous modifications whenever required by the business. Novacura Flow is an example of flexible software that can be connected to an ERP system and allow the user to modify a business process at any time. This approach will enable users to respond effectively to ongoing changes driven by production and warehouse operational needs. https://www.novacura.com/wp-content/uploads/2022/08/nc-www-app-creation-in-flow.mp4 The example presented above explains how users can use Novacura Flow, with access to Novacura Flow Studio, environment for developing applications for internal operational needs in warehouses. The warehouse solution for Teknos TEKNOS GROUP OY. is one of the global coatings company from Finland that offers a wide range of paints and coatings for the manufacturing industry, building professionals, and consumers. The company operates in 20 countries in Europe, Asia, and the US, with more than 1500 employees globally. They have achieved outstanding results with their business approach and development in industry-driven product quality. TEKNOS GROUP OY. selected Novacura Flow software in early 2022. Since then, the company has begun implementing Novacura solutions for warehouse operations, which are required in their manufacturing processes. Novacura had the opportunity to speak with Peter Muhonen, ICT Manager, Supply Chain – and RnD Solutions, about recent developments. Improving the warehouse operations Before implementing Novacura Flow, Teknos already used the Novacura service to connect its IFS ERP […]

learn more

Manufacturing solutions for Nolato Gota from Novacura

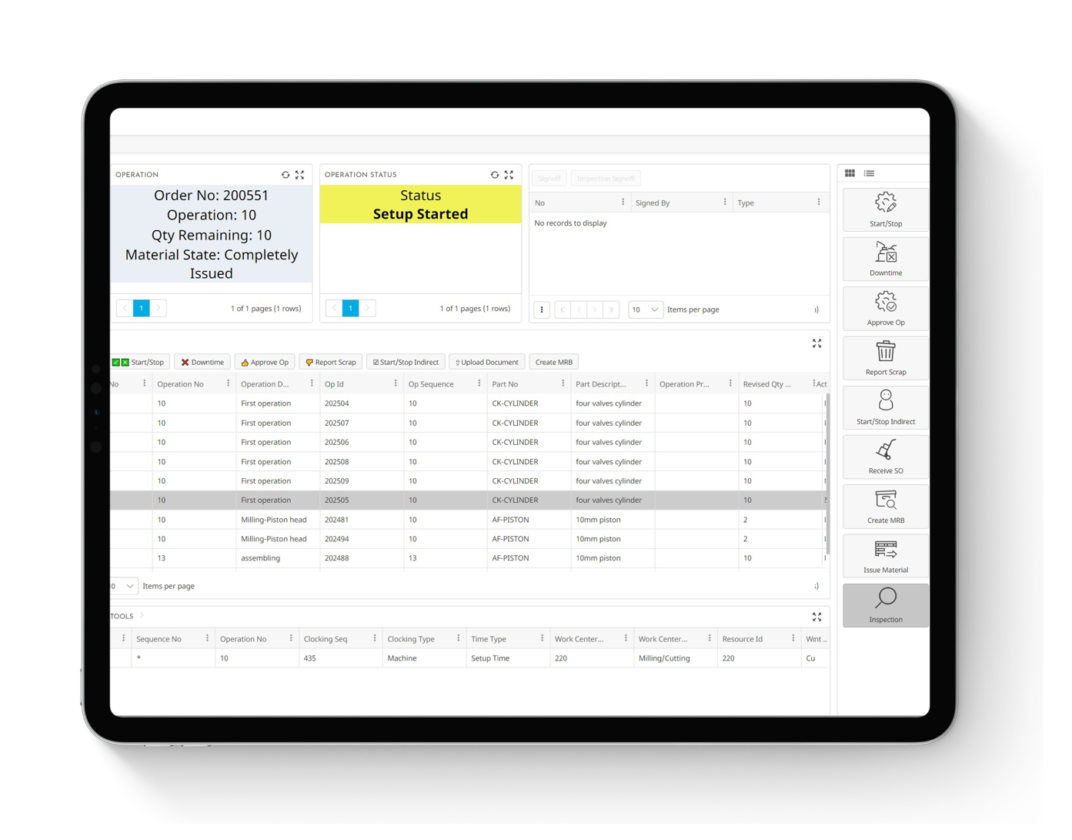

Modern manufacturing is a complex process requiring various components to be effectively integrated at multiple stages. Most of the domestic manufacturing, production, and processing plant equipment consists of electromechanical systems combined with programmable logic controllers (PLCs). This equipment helps provide an accurate overview of day-to-day operations on the shop floor but can also support other departments involved in the entire production process. Manufacturing inventory software plays a critical role in ensuring seamless integration across these systems. The patterns used by modern manufacturing have their dominant attention to all surrounding operations to increase production efficiency and results over time. At the same time, the plant’s core manufacturing operations include well-organized internal logistics and distribution to continuously deliver raw materials to the production line and streamline shipping processes, supported by warehouse management for manufacturers. STREAMLINE MANUFACTURING PROCESSES WITH NOVACURA SOLUTION Manufacturing companies that want to be the most efficient need to identify all possible methods to help them connect all operations and ensure mobile accessibility. This approach involves digitizing the business on many levels, including optimizing processes with increased ERP for manufacturing industry capabilities. The most effective techniques for streamlining manufacturing and warehouse operations can be offered by software that will connect to the ERP system and allow flexible modifications anytime without involving expensive and time-consuming resources. Novacura Flow is a software that provides a comprehensive solution for manufacturing and warehouse processes. The software is connected to the ERP system and allows users to build business applications, offering low-code manufacturing solutions for greater flexibility. The resulting solution enables continuous improvement of existing processes, supporting real-time production tracking and better operational control. https://www.novacura.com/wp-content/uploads/2022/08/nc-www-app-creation-in-flow.mp4 The example presented above explains how users can build own app with Novacura Flow, that gives its users access to Novacura Flow Studio, environment for developing applications for internal operational needs in manufacturing industry. WAREHOUSING SOLUTION FOR NOLATO GOTA Nolato Gota is a Swedish company that offers comprehensive solutions for the automotive market and general industry. The company specializes in producing advanced plastic products with significant technical content. Their operations must comply with IATF and ISO certification to maintain the highest quality for their customers. Leveraging manufacturing inventory control software ensures compliance and operational efficiency. Nolato Gota is part of the Nolato Group, which already has more than 10 years of experience with Novacura Flow software. Nolato Gota has seen significant growth with Novacura Flow in various areas closely related to production, warehousing, and shipping. Facing daily operational challenges, they achieved milestones that improved their processes through digital transformation in manufacturing. Novacura had the opportunity to speak with Jan Färén, IT Manager for Nolato Gota, and together we reflected on the positive impact of Novacura Flow on all of the company’s operations. An example the Novacura app on a mobile device. BARRIER in MANUFACTURING Handling Unit functionality in ERP – the Nolato Gota process with creating handling units as reserved for shop orders before receipt and full tracking through the entire process from production to shipment would have […]

learn more

Mobile approach to manufacturing operations in Nolato Cerbo

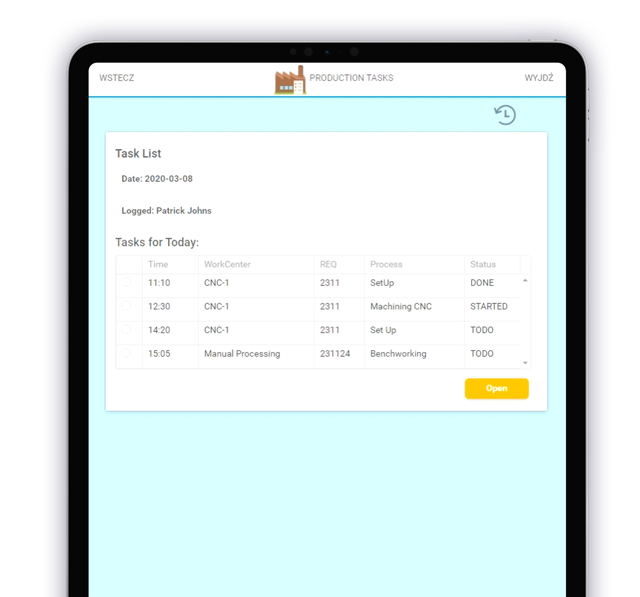

Manufacturing processes require continuous improvement, which is closely linked to warehouse management and product distribution. All internal processes in the manufacturing industry depend heavily on the efficiency of employees and the software systems in use. Companies that produce high-quality products understand the significance of these factors. A lack of improvements in these areas can result in low productivity, ongoing customer dissatisfaction, and rising costs. Novacura solution for manufacturing In order to streamline production processes and internal logistics, companies are eager to establish greater autonomy within their existing systems. This approach involves expanding the capabilities of the ERP system with mobile solutions to manage internal operations. Novacura Flow is an example of a comprehensive software solution that enables users to create manageable applications directly linked to the ERP system. With this type of solution, customers can meet the demands of the manufacturing industry. Inventory management solution for Nolato Cerbo Nolato Cerbo, a Swedish company that specializes in developing medical solutions and manufacturing complex product systems and components within the medical technology sector, along with advanced packaging solutions for pharmaceuticals and dietary supplements, operates in over 10 countries. The company has experienced significant production growth over the past few decades, characterized by high customer satisfaction worldwide. Nolato Cerbo has been using Novacura Flow software for nearly a decade. During this period, the company has successfully addressed many common challenges in their industry. Novacura had the opportunity to speak with the Head of IT at Nolato Cerbo, Per Boensson, and their conversation highlighted significant areas for improvement in their production and warehousing processes. Improving the quality and warehousing Before the implementation of Novacura Flow in Nolato Cerbo’s operations, the company encountered several issues, including: ERP gaps: The IFS ERP system could not adequately cover all of their operational requirements. Warehouse errors: Errors in tasks related to warehouse relocations, stock control, or disposals in production were impacting picking lists and reporting. Time vs. manual operations: Manual warehouse tasks were time-consuming and often not executed with the expected level of accuracy. Paperwork: The extensive amount of printed documentation was affecting warehouse personnel, resulting in reduced productivity. To address these challenges and seek improvements in these areas, Nolato Cerbo made the decision to find a software solution that could enhance the capabilities of their ERP system, allowing them to operate with fewer limitations. When we moved to IFS, our goal was to reduce all side systems that contain data and have as much as just goes into the business system. We also had a lot of manual routines with forms etc. that we updated directly in IFS. We immediately had some flows that we saw problems with managing such as our business looked then. Per Boensson Nolato Cerbo, IT Manager Mobile solution for inventory and manufacturing Nolato Cerbo collaborated with Novacura to develop a range of solutions. Among these solutions, the company created its own mobile applications designed for warehouse personnel with various purposes. In Production we also did Disposal and Warehouse relocation from paper notes and entered data manually in IFS […]

learn more

Maxon Group uses Novacura Flow to improve the operational efficiency of its warehouse

Just as businesses rely on maxon to power essential tools and industrial applications, maxon relies on Novacura Flow to improve efficiency and visibility throughout its warehouse. For the last 60 years, maxon Group has been a leading supplier in the DC motor industry. As a supplier of high-precision drive systems and a Swiss manufacturer with a manufacturing footprint in 9 countries and a distribution network in 40 countries, maxon sets the bar for quality and durability. Businesses turn to maxon when requirements for high-performing motors are high and compromises cannot afford to be made. As a result, maxon are relied on to drive NASA’s Mars rovers, to power insulin and surgical tools, and in other high-precision industrial applications. To improve visibility into where its products were in the manufacturing process, maxon was looking for a way to automate manual processes and improve efficiency throughout its warehouse. Challenges: Cumbersome paper-based processes Lack of product visibility in the warehouse Out-of-the-box software capabilities not sufficient Customizations took too long to implement Maxon was in the process of upgrading from IFS 7.5 to IFS 10 and was looking for ways to improve the overall efficiency of its operations. To achieve this, they explored warehouse software solutions and strategies for automating warehouse operations with low-code technologies. Several of the processes within the warehouse were still handled by pen and paper. For each paper-based process, a person had to manually document the process, then another person would take the stack of papers and input the records into IFS. This not only caused inefficiencies that impacted productivity but also delayed real-time visibility into where products were in the warehouse. Implementing warehouse automation software and integrating with IFS Cloud warehouse management helped streamline these processes, improving both accuracy and efficiency. We had technology that we couldn´t manage by ourselves. For every change, we had to wait up to two months and now [with Novacura Flow] it´s simple and we can develop by ourselves. When we do need to make changes, we can fix them in one or two weeks at the most. René Blättler Maxon, Business Application Consultant Maxon was also using another 3rd party data collection software to integrate with IFS. The solution itself provided several benefits but lacked the flexibility needed to quickly adapt to change. Any modifications needed, often took months to implement, since maxon could not make any changes on their own. Solution Digitalizing pen and paper processes Product tracking throughout the warehouse Seamless integration to IFS 10 Flexibility to customize on their own Maxon evaluated different warehouse software solutions to handle its warehousing requirements. At the end Novacura Flow was ultimately selected due to the flexibility of its low-code platform including ease of use, connectivity to IFS and the ability to streamline other areas of its business. Once Novacura was selected, maxon’s first step was to identify areas that could be automated. maxon reviewed its business processes, evaluated the new features of IFS 10 and carefully mapped out areas they could improve. The most obvious areas for improvement were those that were previously handled by pen and […]

learn more

Jensen Precast improves delivery efficiency with Novacura Flow

Jensen Precast, one of the largest family-owned precast concrete companies in the US, optimized its proof-of-delivery process and enabled data-driven decisions with the automation of its truck scheduling and dispatch service using Novacura Flow.

learn more