What is a Job Safety Analysis (JSA)?

Safety is always a concern on the job site. Safety hazards can put workers in danger, cause serious illness or injury and potentially lead to devastating lawsuits. That’s why many businesses use the Job Safety Analysis (JSA) to help mitigate health and safety risks on work sites.

But completing a JSA every day, for every job site, requires a lot of time and effort. It can be easy for workers to half-heartedly complete their JSAs, or ignore them altogether—which can lead to serious consequences. So today, we want to discuss the JSA process, and how you can make it easier using Novacura Flow.

Why is it important to conduct a job safety analysis?

A job safety analysis (JSA) is a critical first step in promoting workplace safety. By breaking down specific tasks to pinpoint potential hazards, a JSA helps reduce the chances of accidents and injuries, keeping workers safer on the job.

In fields like construction, conducting a JSA before each shift and prior to starting work offers a proactive approach to identifying risks that might otherwise go unnoticed. Recognizing hazards early on provides an opportunity to address them, whether through elimination, substitution, or mitigation strategies, reducing the likelihood of incidents.

Prevention is key—every accident avoided is a direct result of proactive safety measures and a commitment to zero-injury principles. A well-conducted JSA exemplifies this commitment, reinforcing that safety is not only a priority but a continuous process.

For employers, job safety analysis brings additional benefits beyond worker protection. A thorough JSA can improve job site efficiency by reducing delays associated with unaddressed hazards and compliance issues. Identifying risks in advance allows employers to manage resources more effectively and ensure regulatory compliance, ultimately saving time and reducing operational costs.

Though a JSA is just one part of a broader workplace safety program, its impact on reducing accidents and fostering a safe, compliant environment can be significant.

How many JSAs should a company conduct?

Ideally, you would conduct a JSA for every business process—but that takes a lot of time and effort. Focus your efforts on the processes:

- where previous injuries have occurred

- that are high-risk tasks

You will need to update the JSA whenever conditions change. This can mean changes to equipment, location, or even weather: if the business process changes in any way, you need to review/update the JSA too.

You should also review and update the JSA whenever injuries occur on the job.

Best practice is to review, and update as required, prior to beginning the task.

How to create a JSA

Map the process

Maybe you’ve already done this. If so, awesome! You’ve already built the foundation of a successful JSA. If not, you’ll want to start by breaking the process down into tasks. For example, if you were to create a JSA for drinking your morning cup of coffee, you might start with something like this:

|

Task |

Hazard |

Recommendations |

|

Pour coffee in cup |

|

|

|

Add sugar to coffee in cup |

|

|

|

Drink coffee |

|

|

Identify the safety hazards associated with each step of the process

For each task, identify the associated hazards. Consider how the following factors might contribute to a hazard:

- People – Do workers have to take specific actions (walking a specific route, for example) for their own safety, or the safety of others?

- Equipment – Is all safety equipment available? Are machines properly serviced? Are there any safety precautions workers have to take when using equipment (chainsaws, for example)? Do workers have all the equipment they need to do the job properly and safely?

- Materials – Are you working with dangerous or volatile materials? Are some of the materials caustic, flammable or poisonous?

- Environment – Are there any environmental hazards to consider? Is the environment very hot, cold, wet, dry? Will you need to walk or work on slippery surfaces? Do you need to pay attention to electrical wires, fumes or gases? Is the environment urban, residential, commercial, rural or something else? What else is happening around the work environment?

In addition, you need to consider:

- The causes of past injuries – were they caused by human error, equipment, materials or environment?

- Legislation or regulatory requirements

- The manufacturer’s instructions for using equipment

|

Task |

Hazard |

Recommendations |

|

Pour coffee in cup |

Coffee too hot, may burn skin/clothing. Pouring too fast may result in spillage. |

|

|

Add sugar to coffee in cup |

Spoon left in cup may poke user in the eye |

|

|

Drink coffee |

Coffee may be too hot to drink |

|

Determine controls for each hazard

In other words, how can you mitigate the risks of each hazard? Consider previous solutions and best practices. Brainstorm ideas with your workers so that everyone’s on board. You may also want to incorporate standards and best practices like those outlined in ISO 45001.

|

Task |

Hazard |

Recommendations |

|

Pour coffee in cup |

Coffee too hot, may burn skin/clothing. Pouring too fast may result in spillage. |

Hold coffee carafe by the handle. Do not touch the glass sides of the carafe. Pour slowly so as to avoid spillage. |

|

Add sugar to coffee in cup |

Spoon left in cup may poke user in the eye |

Once sugar has been stirred into coffee, remove spoon from cup. |

|

Drink coffee |

Coffee may be too hot to drink |

Bring coffee cup to lips. Test to make sure coffee isn’t too hot. If it is too hot, blow on the coffee until it reaches an acceptable drinking temperature. |

IMPLEMENT THE JSA

The JSA is only useful if people actually use it, so user adoption is key. One of the best ways to make sure the JSA is followed is to incorporate it into your other business processes. Add tasks for verifying safety precautions, such as taking/submitting photos of the work area, to your workflows.

This is something you can do easily with Novacura Flow.

Simplifying JSA processes with Flow

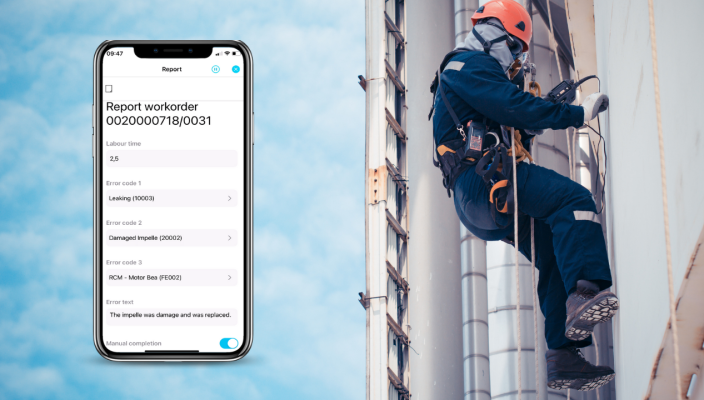

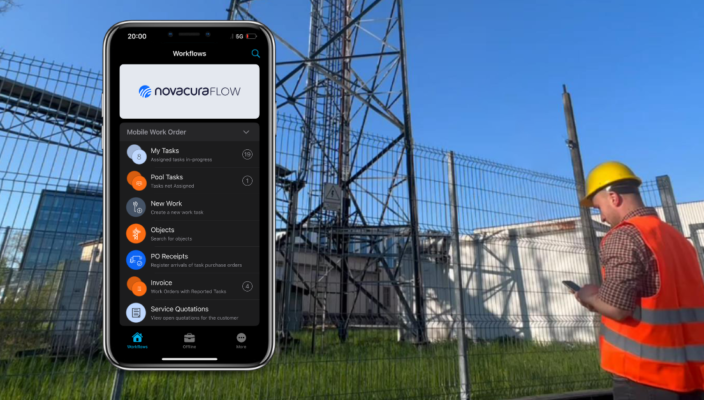

Using Novacura Flow, you can establish a database of digital JSAs. You can embed a review process into your current business process for work order execution, and through Flow’s simple user interface, users can quickly add new revisions to the JSA.

Furthermore, through the use of Novacura swim lanes, approval processes can be embedded into workflows to ensure any organizations segregation of duty policy can be met.

Some of the other ways you can use Novacura Flow for JSAs include:

- submit/upload images of the location

- collect signatures

- collect GPS information

- create forms to make sure people follow the correct procedures

- pull important safety data into the app as required

- barcode scanning (so you don’t have to depend on a touchscreen)

- quickly adapt workflows to changing conditions

Want to learn more about managing JSAs with Novacura Flow? Book a meeting with one of our solution consultants today.