IFS CLOUD:

Manufacturing Module

IFS MANUFACTURING – ALL-IN-ONE ERP SOFTWARE WITH MULTIPLE MODES AND FULL FLEXIBILITY

IFS Cloud Manufacturing: The flexible solution for all your manufacturing needs.

With IFS Cloud Manufacturing software, you can manage every stage of your manufacturing process with ease. Whether you need to plan, execute, control or analyze your production, you can do it with one solution that supports multiple types of manufacturing. You can also enjoy a simple and automated workflow that takes care of routine tasks and catches exceptions. Plus, you can benefit from lean principles and mixed-mode manufacturing, where you can use different processes in the same environment. All this makes IFS Cloud the best ERP software for manufacturing.

COMPLETE SOLUTION

Sales and operations planning

IFS Cloud allows organizations to align their manufacturing supply with their demand and create a realistic production plan. Control different aspects of their business, such as sales, finance, capacity, sourcing, and inventory. Plan monthly at an aggregate level and adjust their plan according to changing conditions.

History for comparison, progress and trends allows organizations to store and analyze historical data on the performance of their sales and operations planning process. It helps to evaluate the results, monitor the progress, and identify the trends of their manufacturing activities. It also enables them to compare different scenarios and plans and learn from their past experiences.

Material and resource planning

Match material supplies and resource capacity with their real and forecasted demands on an operative level.

IFS Cloud allows to break down finished goods requirements into components and semi-finished goods using IFS material requirements planning.

It also helps calculate and analyze resource requirements from various demand sources such as master schedule, material requirements planning, order proposal, dynamic order processing (DOP) and more using IFS capacity requirements planning.

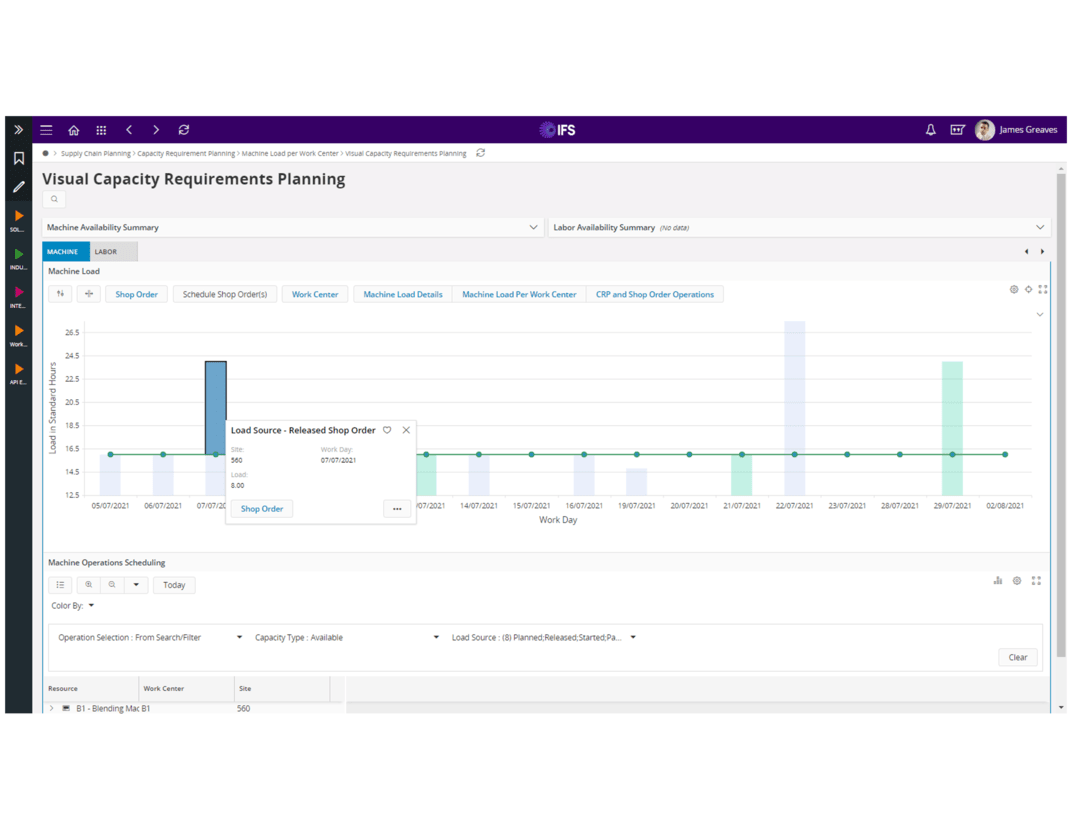

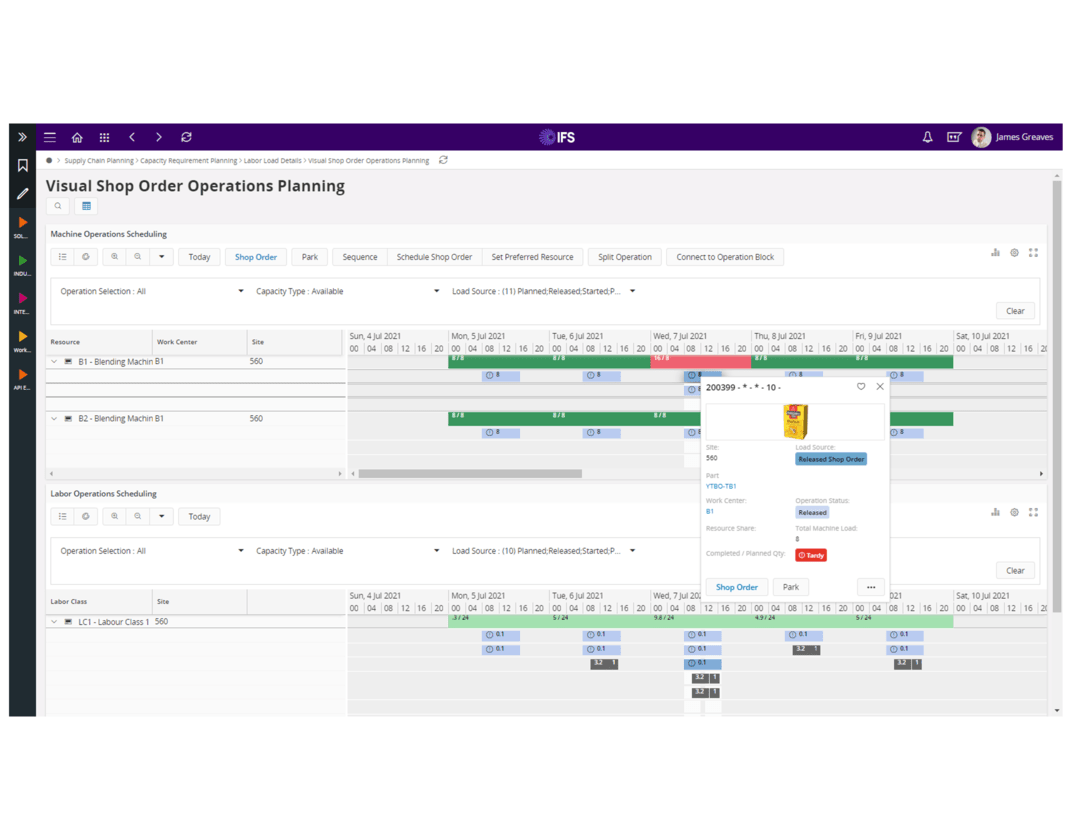

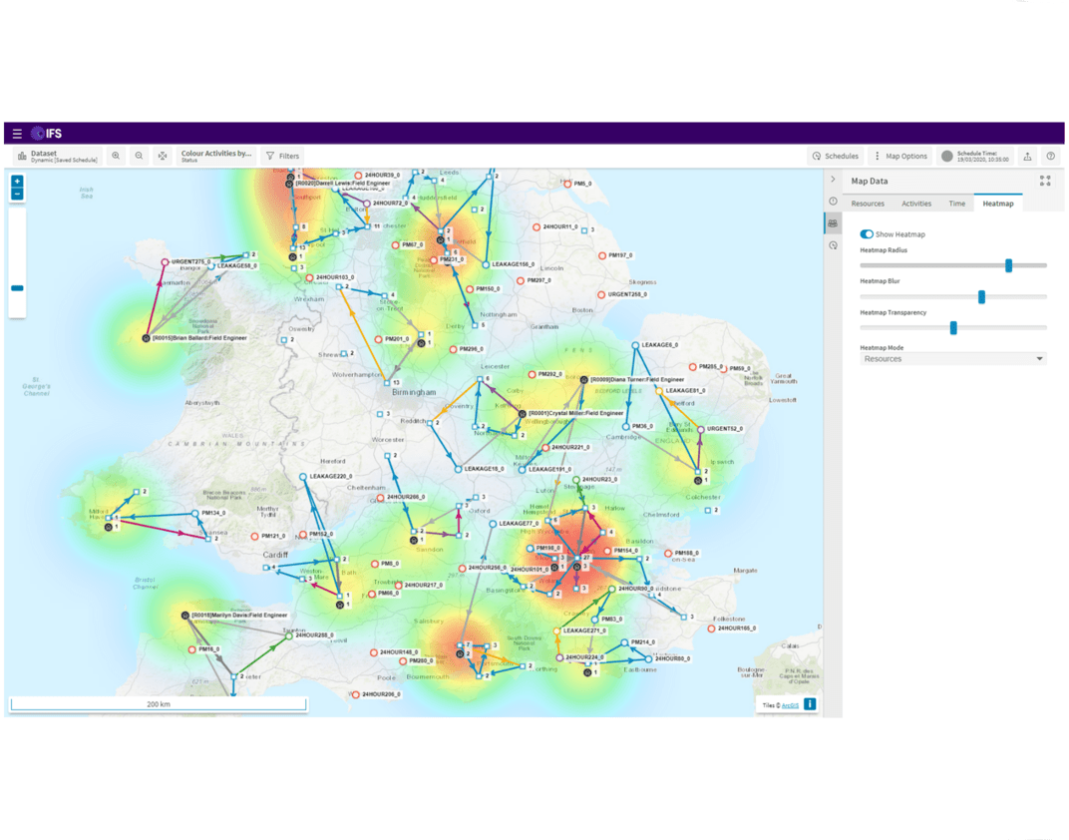

Visual planning and scheduling

Optimize manufacturing production plans by using visual and interactive tools. It shows the demand and supply of resources, materials, and operations in a graphical way, and enables users to quickly identify and resolve any capacity or material issues, sequencing, set up optimization, and operation block planning.

These features of manufacturing ERP software improve the visibility, accuracy, feasibility, realism, utilization, efficiency, quality, throughput, performance, and communication of the production plan. They also help users to meet the delivery deadlines, satisfy the customer expectations, reduce the setup time and cost, avoid waste or rework, handle unexpected events or changes in demand, and plan for future scenarios or what-if analysis.

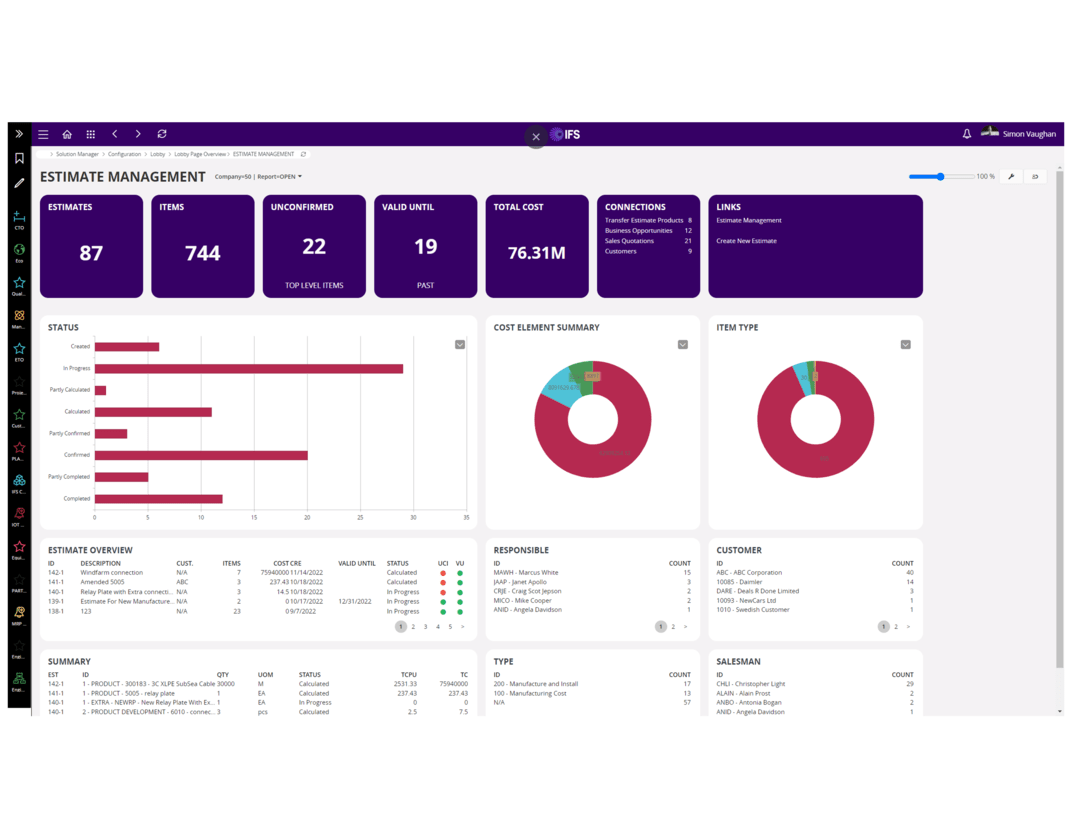

Product estimate management

IFS Cloud Manufacturing helps to create accurate and profitable price estimations for products when quotations are submitted.

Calculate the best possible bid price by considering the cost and build-up of the product and support make vs buy decisions.

Reduce costs and increase win rates by providing fast and reliable responses to enquiries. It has various features that allow users to manage, calculate, compare, adjust, and generate the price and cost of the product based on different scenarios, factors, parameters, and requirements.

Configure and make to order

With IFS Cloud configure & make to order, manufacturers can easily handle and control the production to order industry process, from complex make-to-order (MTO) to simple assemble-to-order (ATO), including multilevel pegged (DOP) structures.

It also helps them use IFS sales configurator to steer the user and customer toward a configured product that can be sold and produced based on the chosen characteristics and option values. Create and manage rules and templates for sales and back-office configuration, and generate consistent and accurate quotations, orders, bills of materials, routings, and cost estimates for their products.

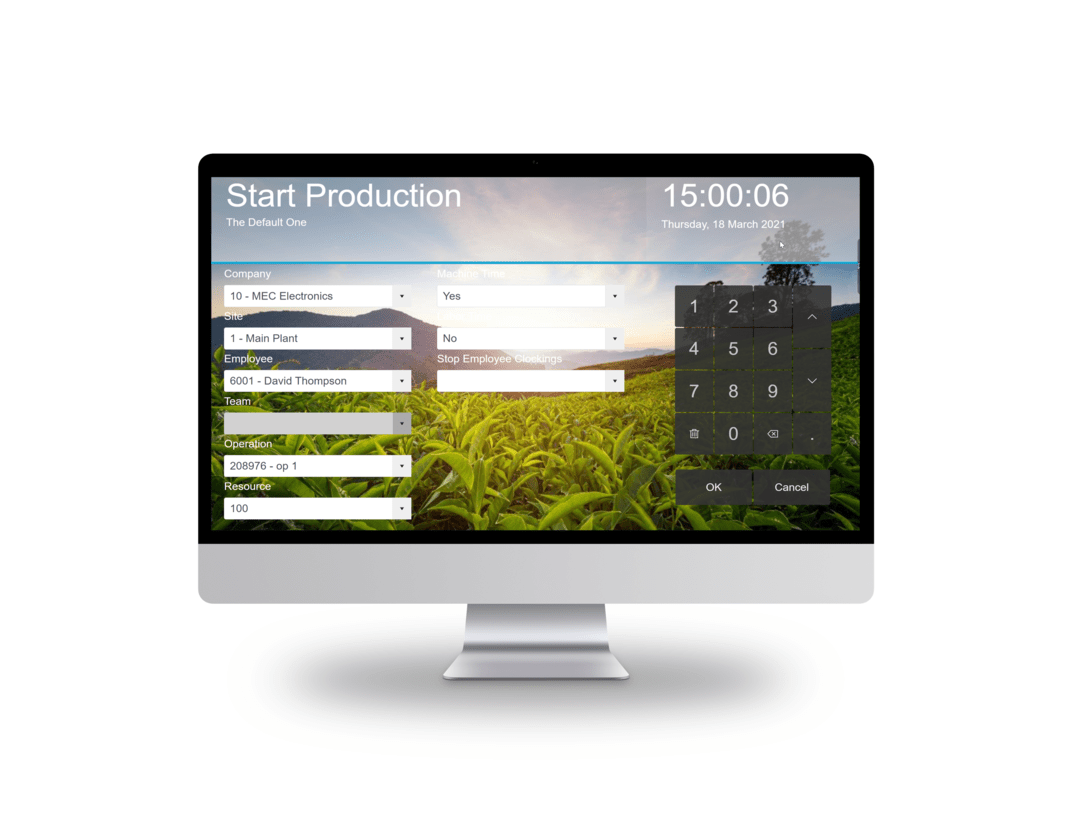

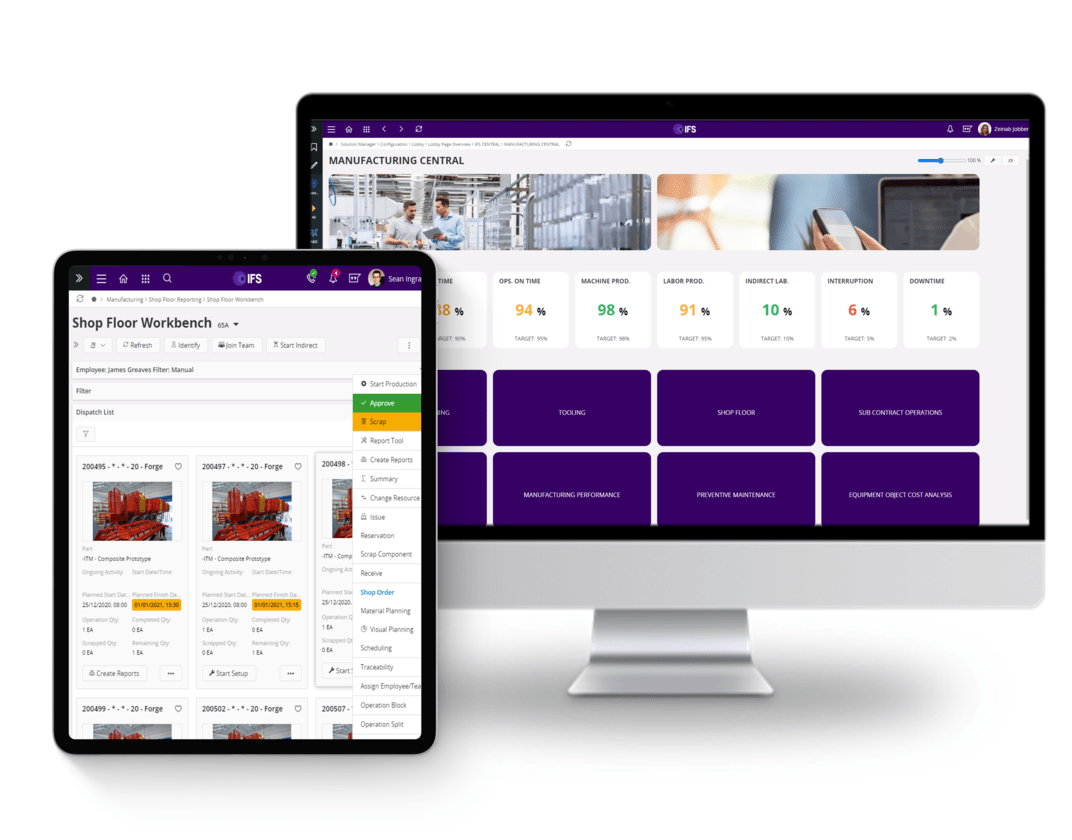

Discrete manufacturing

IFS Cloud Manufacturing is a solution that supports the production process of discrete manufacturing from start to finish. Check the material availability, schedule the operations, consider the tools and labor, and manage the quality of the products.

It also provides flexible options for reporting the operations and material transactions, such as shop floor workbench, which allows users to quickly report the operation clocking’s, machine downtime, and issuing of materials.

Design to delivery, with features such as BOM and routing with embedded PLM, prototype inspection, shop floor reporting from IoT-connected machinery and integrate external systems with restful APIs from MES/Scada. IFS Cloud manufacturing is recognized as the best erp module for manufacturing.

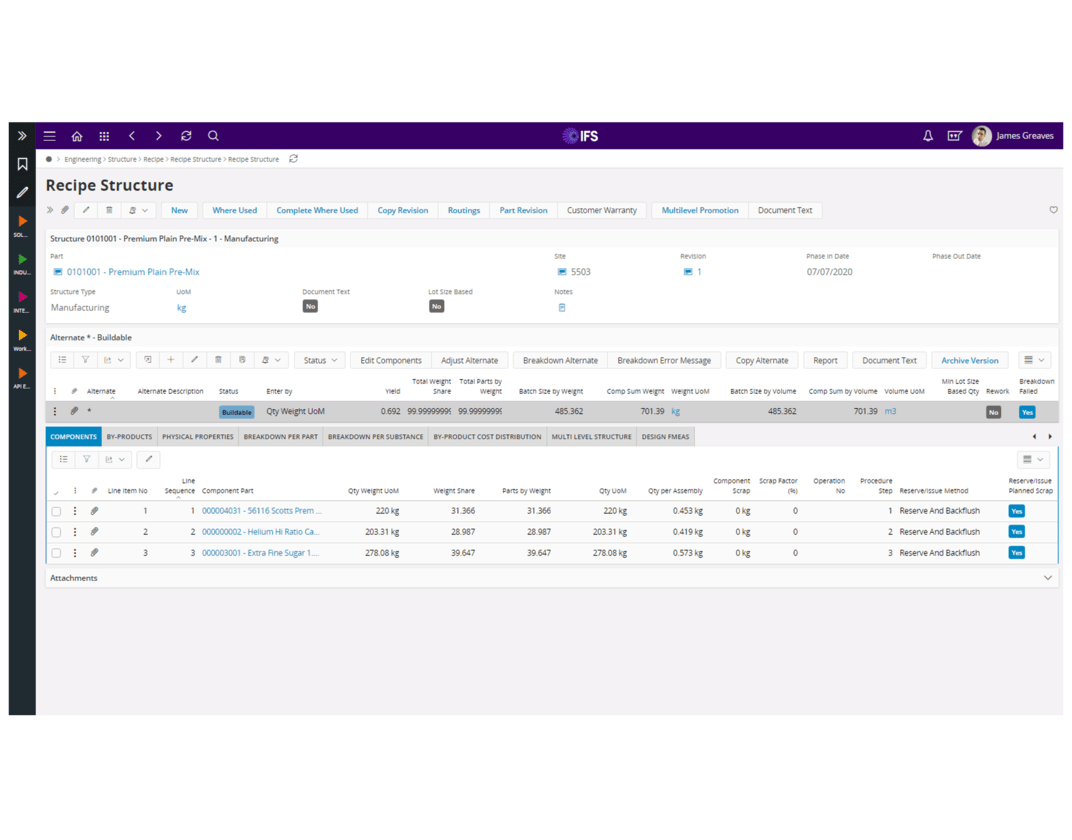

Batch process manufacturing

IFS Cloud batch process manufacturing is a solution that supports recipe/formula-based manufacturing for industries such as food & beverage, pharmaceutical and chemical.

Track the materials and products from raw to finished stages, balance the batch sizes according to the restrictions on different levels. It also helps users to sequence the products based on their characteristics to reduce the changeover cost.

Create and manage recipes and formulas, rework faulty batches, control shelf-life, track materials and products, use multiple units of measure, and check material availability for their company batch products. The solution also has features for quality management such as control plans and analysis.

Repetitive manufacturing

Improve production efficiency and flexibility by using features such as Kanban replenishment, takt time planning, production schedules, supplier schedule generation, and order-less production. Reduce the inventory and waste and replenish the materials and products from and to different production lines and locations with IFS Cloud Kanban module.

Takt time planning helps you balance the supply and demand and optimize the production rate and capacity based on the customer demand. Production and supplier schedule generation helps users to communicate and coordinate and make sure the materials and products are delivered on time and correctly. It helps also to produce without using shop orders and make the production process faster and simpler with order-less production.

Quality management

Quality management in IFS Cloud is a solution that helps to improve the quality and productivity of products and processes across the entire value chain.

It covers both quality control and quality assurance and enables the analysis and correction of non-conformance issues.

It also supports various quality management tools and methods, such as control plans, sampling, SPC charts, FMEA, audits, NCR, MRB, and CAPA.

Sustainability management

Manage the environmental impact of your products and processes throughout the entire lifecycle and supply chain. Generate material declarations and environmental product declarations and environmental reporting, such as the Global Reporting Initiative.

Comply with various environmental regulations and standards, such as Reach, RoHS, WEEE, and ECO-labels, which are related to the use of hazardous substances, waste management, and energy efficiency.

Track and analyze non-conforming parts, which are products or components that do not meet the quality or environmental requirements. Implement circular manufacturing operations for recycling or remanufacturing purposes.

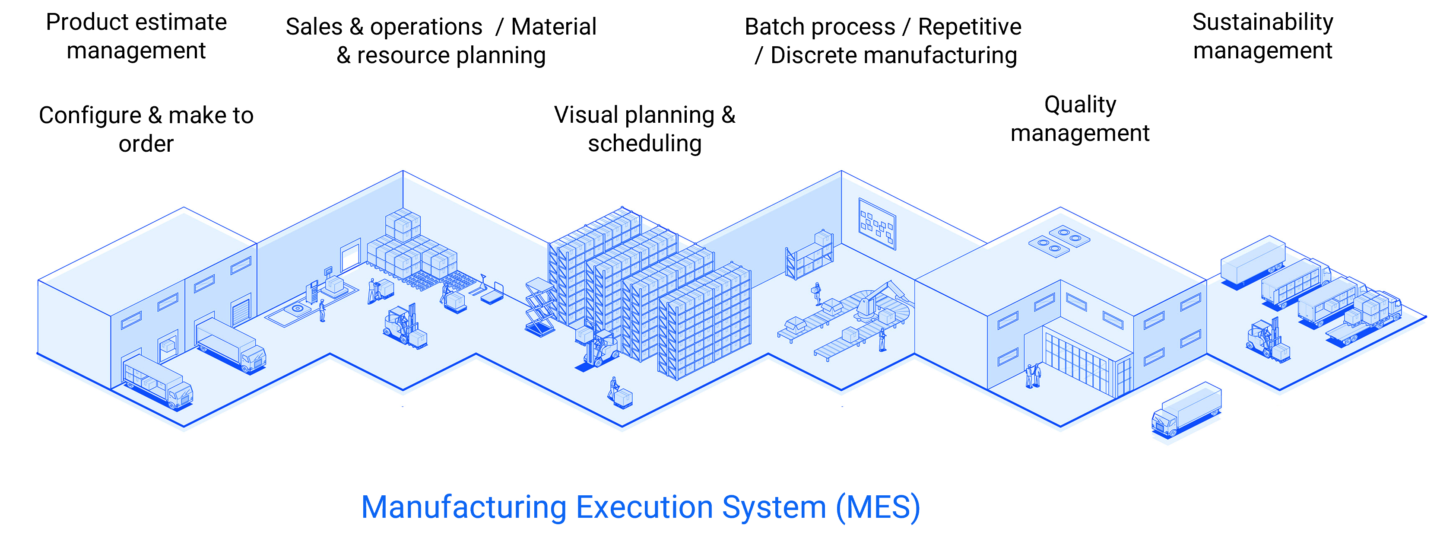

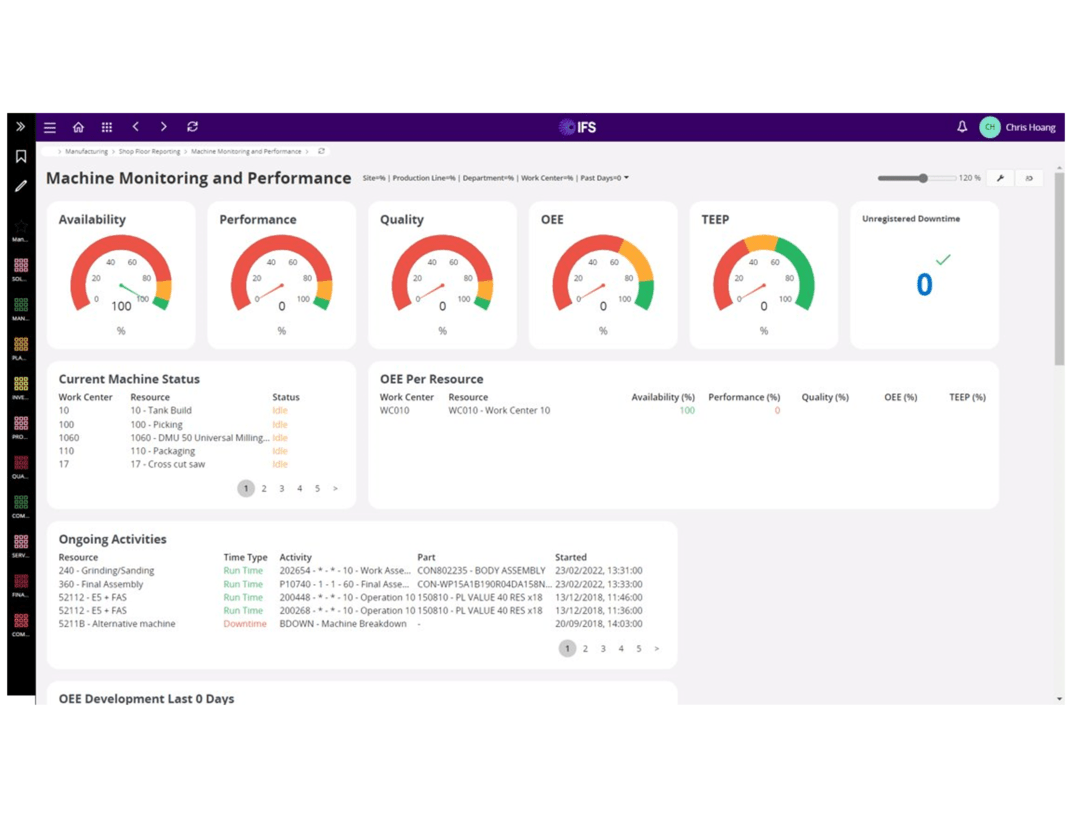

Manufacturing Execution System (MES)

IFS MES is a software solution that integrates with IFS Cloud to help manufacturers optimize their production processes and improve their equipment performance.

It collects and analyzes data from shop floor machines and devices and enforces the planned manufacturing procedures. It also provides features for scheduling, dispatching, quality management, resource management, reporting and KPIs.

IFS MES aims to increase the Overall Equipment Effectiveness (OEE) of the manufacturing operations and enable faster decision making and problem solving.

UPCOMING FEATURES

The IFS Cloud is an evergreen solution. It creates value for users by providing instant access to continuous software innovations and upgrades. Major changes are delivered twice a year, in Spring and Autumn.

- Manufacturing Scheduling & Optimization;

- Automatic Issue of components in MES;

- Order Promising and simulation in MSO;

- Identifying ESG data in IFS Cloud’

- Organizational Carbon Footprint Calculations for Scope 1, 2, 3 Emissions;

- Identifying ESG data in IFS Cloud;

- Introduction of ESG Lobbies;

- Support for Circular Manufacturing (support for remanufacturing including offering the ability to cost calculate both disassembled components and remanufactured parts).

IFS CLOUD CUSTOMERS :

List of customers using IFS Cloud obtained from official IFS promotional materials (IFS Cloud).

TECHNICAL highlights:

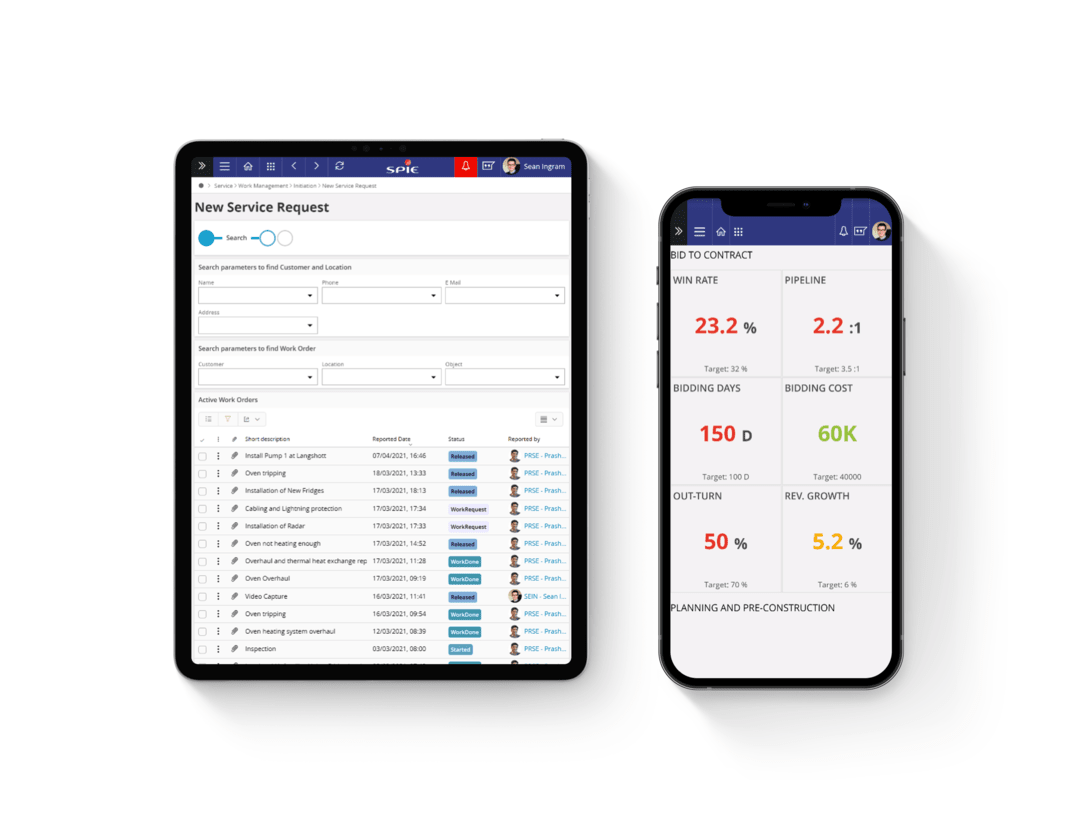

Completeness and servitization

IFS Cloud Service Management offers complete control, optimization, innovation and connectivity across the entire service lifecycle. It covers all aspects of service management, such as field service, contact center, contracts, warranties, parts, logistics, remote assistance, and more. It is a single platform that addresses the full-service lifecycle.

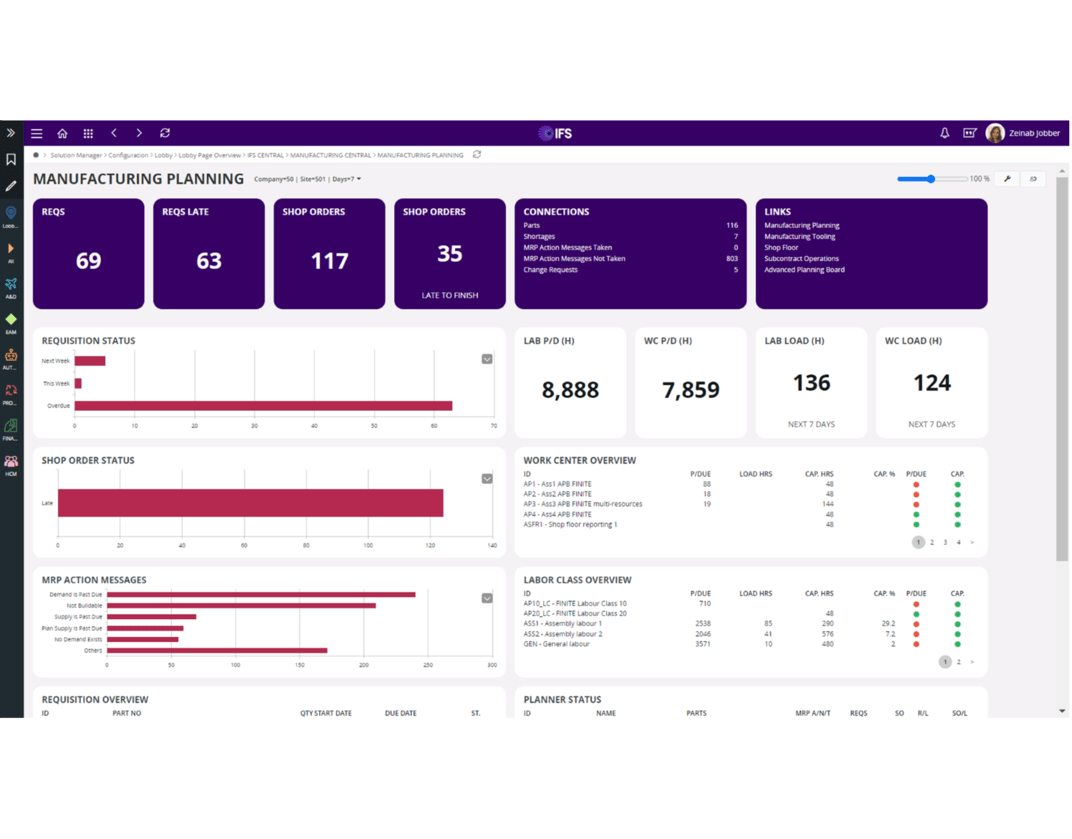

Smart manufacturing

As an ERP software for manufacturing, IFS Cloud is a platform that enables you to optimize your manufacturing operations with real-time data and insights. It integrates with your devices and machines through IoT capabilities and provides you with MES capabilities to manage your production processes.

MES in IFS Cloud is a smart solution that helps you connect, capture, and control your shop floor data in real time. It enables you to automate your production reporting and quality control and improve your OEE.

It also helps you identify and resolve issues quickly and make faster and better decisions. You can monitor and improve your efficiency, visibility, and decision making with IFS Cloud.

Automatization

IFS Cloud: Intelligent automation for your business. IFS Cloud is a platform that helps you automate and optimize various tasks with application and robotic services. Application services use AI techniques such as RPA, ML, NLP, and chatbots to process data, make decisions, and communicate.

Robotic services use robots or robotic arms to perform physical tasks that need precision, speed, strength, or endurance. They simplify and automate repetitive tasks, while also handling exceptions and lean principles. Integrate efficient ERP software module solutions into your business processes with IFS Cloud.

Modern user interface

IFS Cloud delivers delightful experiences, with responsive, people-first design, and provides you with the IFS Lifecycle Experience and portals that support how you buy, implement, operate and extend every step of the way. You can also access your data and applications from any device, anywhere, anytime.

Innovative platform

With IFS Cloud, you can access all our best-in-class solutions from a single product, built on a common platform, and enable the capabilities you need today, with AI built-in functionalities, and add more as your business needs change, with one consistent user experience, underlying infrastructure - and new feature updates every six months. Manufacturing ERP solutions are seamlessly integrated and provide comprehensive and adaptive capabilities for manufacturing organizations.

Deploy wherever you want

IFS Cloud is a flexible and scalable solution that can adapt to the changing needs of service organizations. It can be deployed on-premise, in the cloud, or as a hybrid model. It can also be configured and customized to suit different industries, geographies, and business processes. It can support any size of service organization, from small to large.

Always up to date (Evergreen)

IFS Cloud is a cloud-based solution that delivers the most advanced features and functionalities for your business needs. It follows a regular development plan with releases twice a year, in half year intervals, with versions R1 and R2. This ensures that you always have access to the latest innovations and improvements from IFS Cloud, without having to worry about the maintenance and upgrade costs. IFS Cloud is the smart choice for staying ahead of the competition.

Ready for modification and expanding

IFS Cloud is a solution that can be easily extended and customized to meet your specific business needs and preferences. One of the tools that you can use to extend IFS Cloud is Novacura Flow, a low-code platform that allows you to create your own ERP applications by simply drawing them in a graphical interface. Novacura Flow also offers business process management and integration capabilities, as well as a library.

DETAILED LIST OF CAPABILITIES:

Below we summarize the list of areas supported by IFS Cloud Manufacturing:

01:

Sales and operation planning

- Strategic and tactical planning

- Demand and capacity simulation at product family level

- Production, procurement and inventory plan co-ordination

- Resource requirement planning

- Resource constraints visibility

- History for comparison, progress and trends

02:

Material and resource planning

- Master scheduling

- Capacity requirements planning

- Material requirements planning

- Demand driven MRP

- Dependent and independent demand forecasting

- Intraday planning

03:

Visual planning and scheduling

- Visual capacity and material planning

- Finite scheduling

- Operation block planning

- Set up optimization

- Operation sequencing

- Drag and drop scheduling

- Infinite scheduling

- Selection-based filtering

- Interactive displays (visually guides and presents information for warehouse workers using e-label display technology)

04:

Product estimate management

- Scenario based revision and version handling

- Complex price estimations

- Advanced cost and build-up functionality

- Make vs buy decisions

- Markup and cost contingency

- Support sales opportunity and sales quotation estimation

- Supplier RFQ

- Part, structure and routing generation

- Differentiated inventory planning based on frequency, ABC class, location and lifecycle stage

- Parameters set on groups instead of individual parts

- Direct connection to demand planning with automatic update of ABC class and lifecycle stage

05:

Configure and make to order

- Make to order

- Assemble to order

- Configure to order

- Sales configuration rules and templates

- Back office rules

- B2B for configured sales parts

- Integrated restful APIS for web-front

06:

Discrete manufacturing

- BOM and routing with embedded PLM

- Prototype (first article inspection)

- Shop floor reporting from IoT-connected machinery

- Full-level material traceability

- Time and attendance connection

- Operation block and resource share

- Machine downtime and indirect time

- Outside operations incl B2B

- Integrated restful APIs from MES/Scada

- Concurrent operations reporting

07:

Batch process manufacturing

- Batch balancing

- Recipe formula management

- Rework of faulty batch

- Shelf-life control

- Full-level traceability

- Multiple units of measure

- Simplified material check

08:

Repetitive manufacturing

- Kanban replenishment

- Takt time planning

- Production schedules

- Supplier schedule generation

- Order-less production

09:

Quality management

- Control plans and analysis results

- Acceptance sampling support

- SPC charts and capability indices

- Failure mode and effects analysis (FMEA)

- Quality audit management

- Non conformance reporting (NCR)

- Material review board (MRB)

- Corrective and preventive actions (CAPA)

10:

Sustainability management

- Substances and emission tracking

- Product lifecycle, cradle to grave

- Environmental declarations

- Non-conforming part analysis

- Support for disassembly management (circular manufacturing operations)

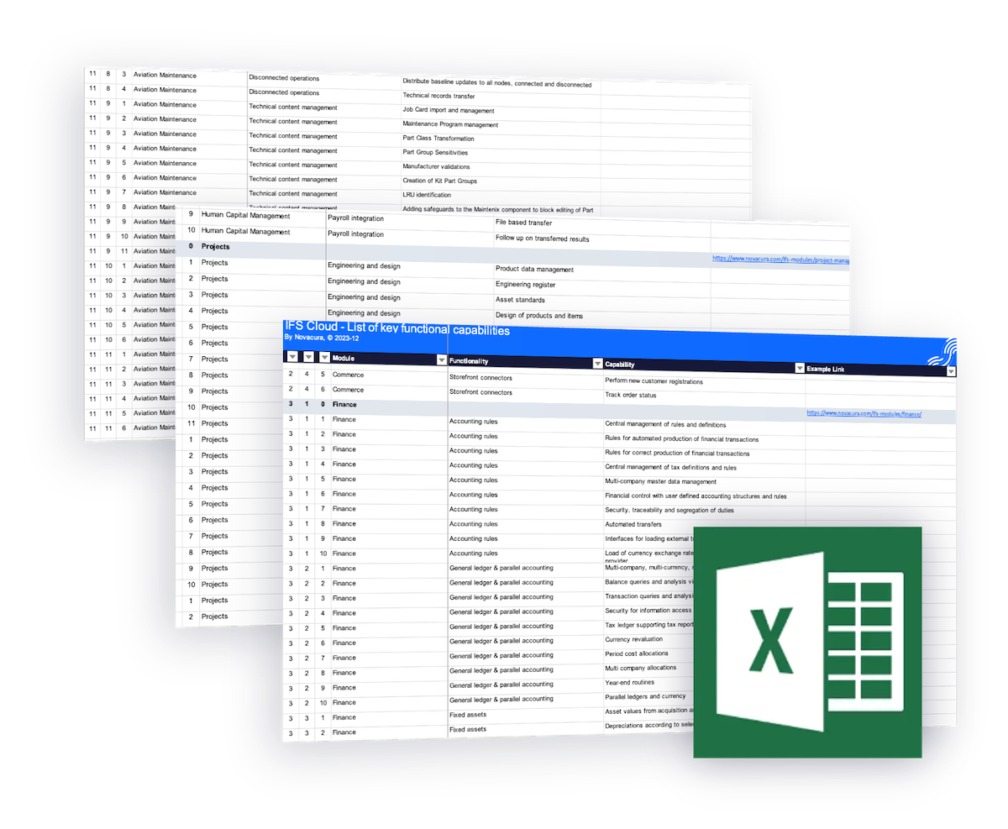

List of IFS Cloud Modules, Functionality and Key Capabilities

Explore 11 modules, 90 functionalities, encompassing a diverse range of 765 capabilities. Download the list highlighting the key functional capabilities provided by IFS Cloud (2023-R2). Novacura – Trusted by 220+ Companies.

How to implement:

CONTACT OUR EXPERT:

Östen Westman

IFS Expert

Looking for personalized advice? Feel free to ask Östen about how Novacura can tailor solutions to your business. Fill out the form, and we’ll get back to you shortly!