The main goal for any industry is to use the ERP system more productively to remain competitive with other companies. A successful ERP implementation and planning the right framework for the entire project can raise many questions, as different industries have their own requirements.

Error-free ERP implementation in an organization requires more involvement from experts and other resources. Once an ERP system is in operation, after GO-LIVE, it may require more comprehensive support with mobile solutions that can directly improve all operations. Implementing mobile control in operations can benefit industries such as manufacturing, logistics, service, maintenance, and others by making systems more productive

How ERP implementations fail?

In most industries, any ERP implementation requires a commercial-off-the-shelf (COTS) deployment. The ERP must be well-suited to meet operational needs and improve business performance through better-developed processes than its business competitors on the market.

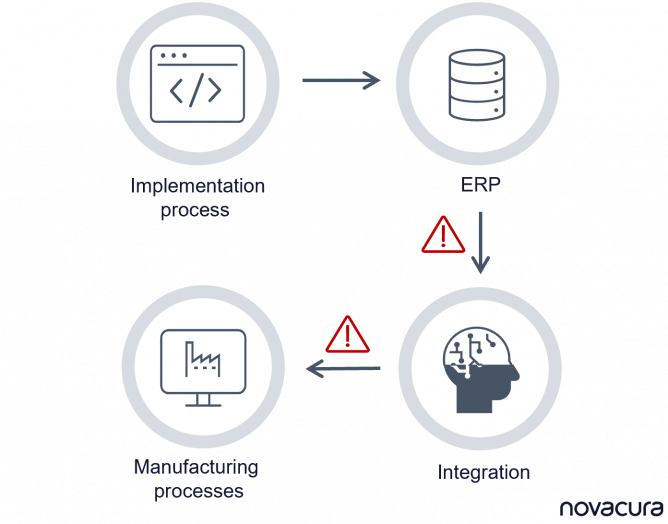

Implementing an ERP system is a long-term project in which many things can go wrong. One example of an ERP failure relates to the system’s integration with manufacturing processes. During the ERP implementation, the company encountered serious problems with data retrieval. The system was supposed to process 40,000 operations in a certain amount of time, but the floating-points showed that it was actually only 20,000. This calculation error resulted in a significant modification, while the ERP system had not yet been fully implemented. The main cause in this particular scenario was a miscalculation of the system configuration required to complete the project within the scheduled timeframe.

After implementing the ERP system, more performance gaps became evident, and these couldn’t be resolved quickly. As a result, the company’s employees had to carry out certain operations in a highly inefficient manner, resorting to manual methods and relying on traditional printed documentation.

This could have been avoided from the very beginning if the company had been able to consider mobile solutions on its premises simultaneously implemented with ERP.

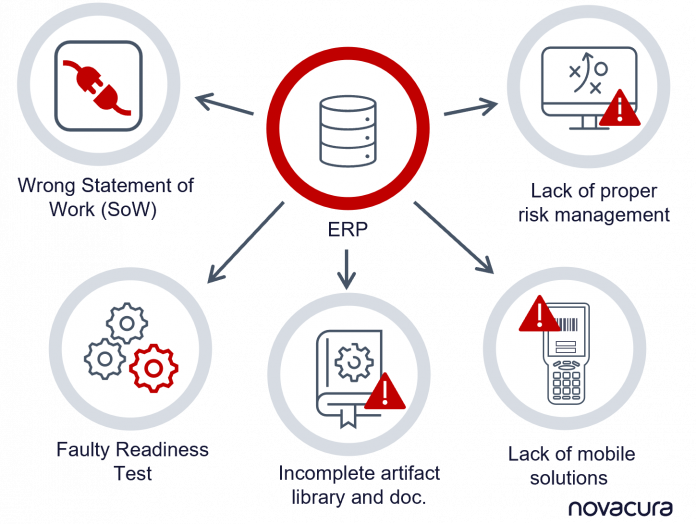

Here are the key factors that can lead to failures during and after ERP implementation:

-

The lack of a proper risk management strategy – initiating an on-site ERP implementation strategy and a migration plan from the existing system are best practices in any project approach. However, each step should be evaluated for risks to avoid costly delays.

-

A wrong Statement of Work (SOW) – project procurement should be recognized as integral to any plan to keep the business safe during and after implementation and when determining ROI results.

-

An incomplete artifact library and documentation list – a wrongly mapped business case and an incomplete roadmap without an incorporated scope management plan and an incomplete user service level agreement (SLA) can affect the final project results.

-

The faulty Readiness Test – a lack of properly conducted simulations can result in the failure of ERP capability assessment before the GO-LIVE stage, which may even affect a very robust functional specification.

-

The lack of mobile solutions – no mobile devices deployed on premises with ERP may lead to higher business expenses and affect operational performance after implementation.

Why ERP implementations fail?

- Set the ERP implementation team

- Create an effective change management plan

- Communicate with diverse groups

How to avoid implementation failures?

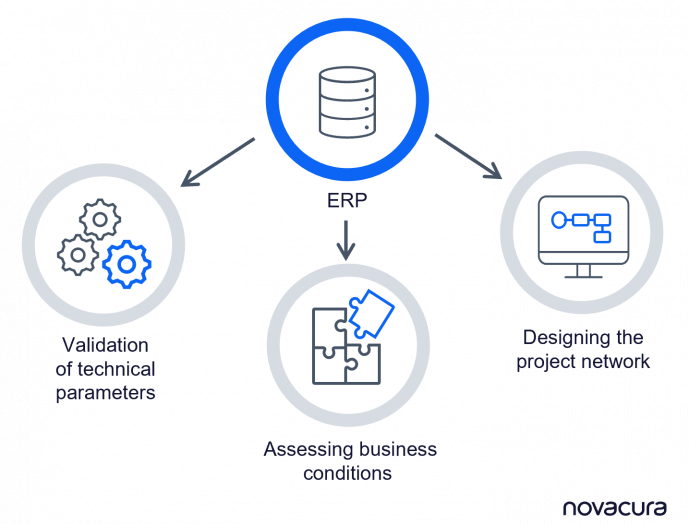

ERP implementation requires a well-prepared framework and several elements that can lead the project to successful execution. We can outline important project dependencies that can be included to guide the collaboration between the various departments and teams involved. Here are the project dependencies:

-

The validation of technical parameters – evaluation in terms of the service level agreement (SLA) and consideration of hardware and software requirements, along with post-release system maintenance.

-

Assessing business conditions – implementing a configuration management (CM) plan to assess the preconditions of the entire project and to determine the status of the project with key elements, such as mobile solutions for various operations, within the planned timeframe.

-

Designing the project network – properly determining the involvement of internal units and resources that may participate during the project, is a part of risk management that may disrupt the project

Extend ERP capabilities with Novacura Flow

The ERP implementation model can vary and is strictly dependent on the business profile and industry requirements. Even after successfully implementing an ERP system, it may not be able to cover the expanded industry requirements that are constantly changing in a very dynamic business environment. It’s worth noting that ERP modifications at this point can be very expensive and time-consuming. To avoid modifications and keep the ERP system evergreen, a company can consider using low-code technology that allows for the development of customizable applications integrated with ERP.

The example presented above illustrates the implementation of IFS ERP system with Novacura Flow (Novacura – dark blue elements).

-

Initiation: Novacura employs the IFS methodology to introduce an ERP system, incorporating the most frequently used modules for project management, maintenance, finance, procurement, inventory, HR, and more. During this stage, the ERP system can be newly installed or assessed for potential upgrades.

-

Confirm Prototype: Novacura introduces its mobile solutions for internal use in conjunction with IFS.

-

Establish: Adapt Novacura Flow to the business environment and test the application’s performance with IFS. Users can design and create their mobile applications.

-

Implement: Conduct appropriate simulations, tests, and validations to ensure expected results.

-

Go Live: Launch Novacura Flow in synergy with the IFS ERP system.

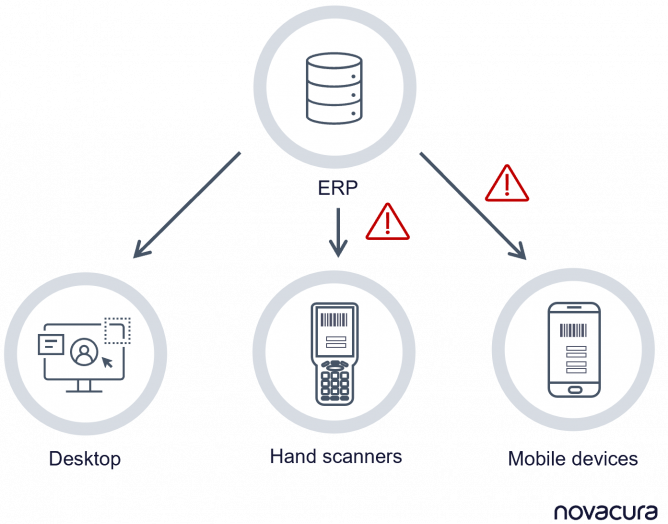

Novacura is implementing ERP systems and give an access its users to the Novacura Flow Next-Generations low-code platform. Novacura Flow allows its users to build desktop and mobile applications for various devices full integrated within the ERP system.

The example presented above explains how users can build own app with Novacura Flow, that gives its users access to Novacura Flow Studio, environment for developing applications for internal operational needs in every industry.

Benefits of IFS implementation with Novacura Flow

Novacura Flow and IFS can provide numerous benefits to businesses. Here are some key advantages that have a significant impact on the entire process during and after implementation:

-

Cost reduction and ROI: Novacura offers full support for IFS + Novacura Flow implementation, eliminating the need for additional services and helping reduce overall costs in continuous business improvement processes, thus supporting ROI results.

-

Evergreen ERP: Customers can avoid making deep modifications to the ERP system, preserving its capabilities. All operational changes can be made within the Novacura Flow environment, ensuring the ERP remains unaffected.

-

Easy integration: Novacura provides dedicated connectors, enabling seamless integration between Novacura Flow applications and the ERP system, facilitating data exchange between systems.

-

Mobile solutions: Novacura Flow allows users to work on a variety of devices, from desktop computers to handheld scanners and cell phones, thereby expanding operational capabilities.

-

Fulfilment of specific requirements: The Novacura Flow layer added to IFS significantly expands the functional and technological capabilities of the entire solution.

-

Reduced staff training requirements: The Novacura Flow platform is user-friendly and doesn’t require highly skilled programming staff to build working applications. It also allows for creating applications with a clear interface, making it accessible to employees with varying levels of computer proficiency.

-

Professional support: Novacura’s experts have extensive experience gained from years of direct work with IFS. They understand the industry’s requirements and can provide the best-fit solution for the company.

Summary

The synergy between IFS and Novacura Flow services allows for the extension of business capabilities. Novacura implements the IFS ERP system integrated with Novacura Flow mobile solutions. Our methodology is mature and efficient in terms of time and cost.

Explore our customer cases from around the world where we have successfully implemented IFS and helped our customers increase their operational capacity with the mobility provided by Novacura Flow. Contact us today to learn more about how we can enhance your business operations