3 min to read

3 min to read Odenwald Faserplattenwerk GmbH in Amorbach, Germany, faced challenges in tracking the exact amounts of raw materials used in production. For instance, the company’s mixing machine combines, for example, 800 liters of water, 150 liters of one ingredient, and 50 liters of another to produce 1,000 liters of Kaolin — a semi-finished product used in further processing. However, before Novacura stepped in, OWA could only estimate material consumption, leading to discrepancies in stock levels.

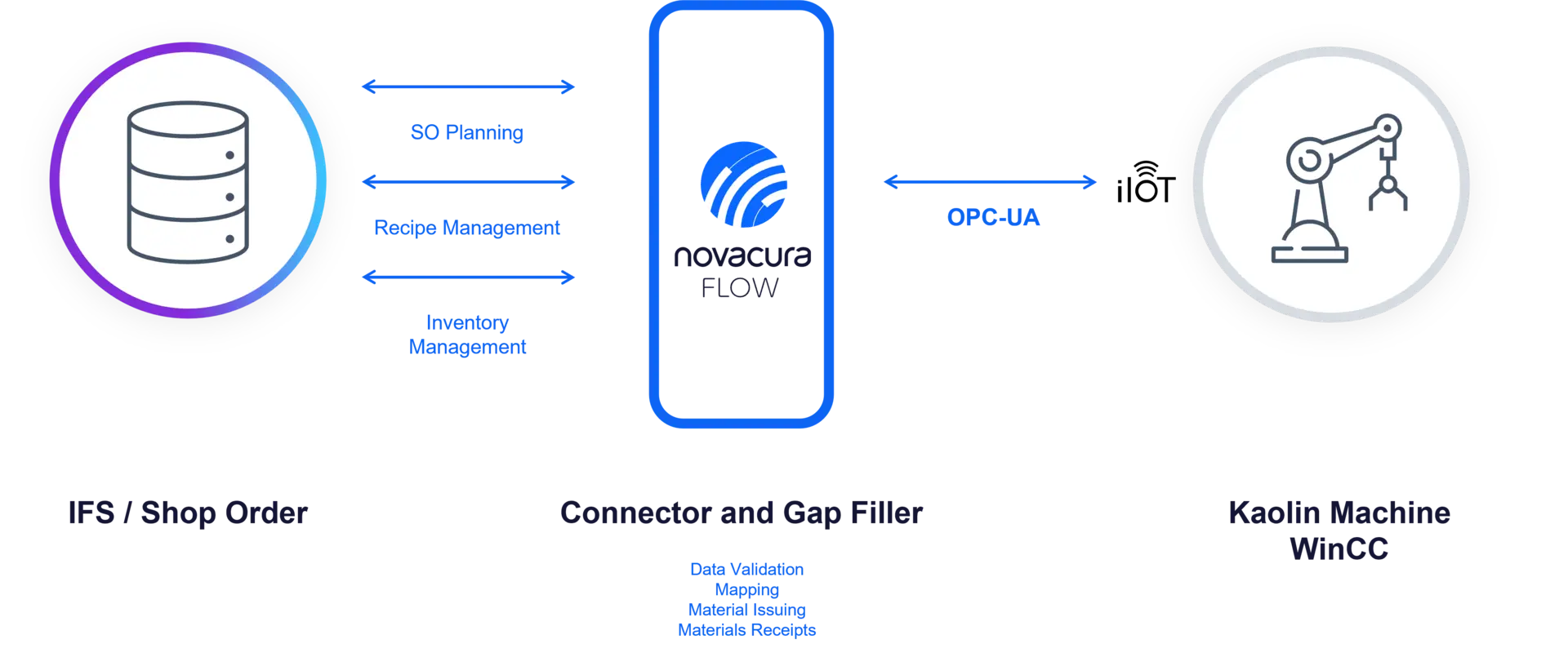

Their ERP system, IFS Applications 10, had no direct way of receiving actual consumption data from the machine. Novacura provided a solution using Novacura Flow as an integration engine to connect the machine with IFS via OPC UA.

Communication Between Systems

Seamless Production Integration: Real-Time Material Tracking

The implementation included two automated workflows:

- Sending production instructions – IFS sends the shop order and recipe details (specific material amounts) to the machine.

- Receiving actual consumption data – Once a batch is produced, the machine reports the actual quantities consumed via OPC UA. Novacura Flow picks up these messages every 10 minutes and registers them in IFS.

This automation eliminated manual estimates, increased accuracy, and improved stock management. The factory now has real-time material tracking, reduced discrepancies, and better synchronization between production and ERP systems.

With this solution, we no longer rely on rough estimates—our material tracking is now fully automated and precise. This has significantly reduced stock discrepancies and improved our production efficiency. - Odenwald Faserplattenwerk GmbH.

From a technical perspective, this case highlights Novacura Flow’s ability to integrate with OPC UA, just as it already does with REST, IFS, Microsoft SQL Server, and email systems. While OPC UA has existed since the 90s, integrating it into modern workflows like this is still an evolving field—one where Novacura excels.

What is OPC UA?

OPC UA (Open Platform Communications Unified Architecture) is a communication standard that enables secure and reliable data exchange between industrial machines and business systems. Similar to how REST connects web applications, OPC UA allows machines and control systems to communicate with computers in factories. This makes it possible to collect and manage real-time production data, improving traceability, efficiency, and automation.

About OWA

For more than 75 years, OWA has incorporated flair and passion in the creation of unique ceiling systems. OWA designs combine tradition with innovation and through a continuous pipeline of creativity, represent real added value for our clients, whatever the application. With outstanding ceiling systems, committed employees, and a consistent focus on service, our company embodies the highest ‘Made in Germany’ quality mark.

Our OWA brand is synonymous worldwide with high-quality ceiling systems that combine design and functionality in a unique way. In line with our commitment to expertise „OWA – more than a ceiling“ we work together with our partners to ensure greater safety and well-being in all building segments.

www.owa.de